Content Menu

● Introduction to Color Steel Sandwich Panels

● Leading Russian Manufacturers and Suppliers

>> Stroypanel LLC

>> SP-Center

>> Panelstroy

>> Metal-Group LLC

>> MetalProm LLC

>> Baikal

● Applications and Advantages

>> Industrial and Commercial Use

>> Key Benefits

>> Customization and Design Flexibility

● Sustainability Efforts

● Advanced Production and Quality Assurance

● Conclusion

● FAQ

>> 1. What core materials are mainly used in Russian color steel sandwich panel manufacturing?

>> 2. Are customization options available for thickness, length, and finish?

>> 3. How do Russian manufacturers ensure compliance with quality and safety standards?

>> 4. What sustainability initiatives are prioritized in Russia's sandwich panel industry?

>> 5. Which sectors commonly utilize color steel sandwich panels in Russia?

Color steel sandwich panels have become a cornerstone in modern construction across Russia, prized for their outstanding thermal insulation, rapid installation capabilities, durability, and versatility in aesthetics. For international buyers, wholesalers, and manufacturers seeking OEM collaborations, understanding Russia's competitive landscape of color steel sandwich panel manufacturers and suppliers is essential. This article offers a comprehensive overview of the key players, innovations, market dynamics, and applications shaping the Russian color steel sandwich panel industry.

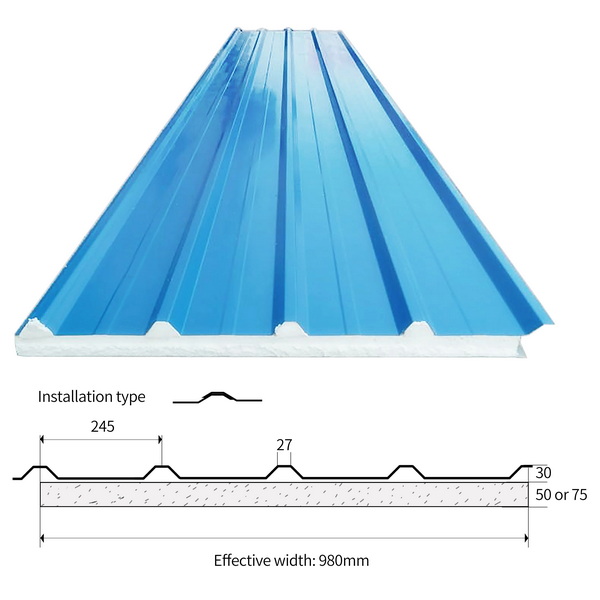

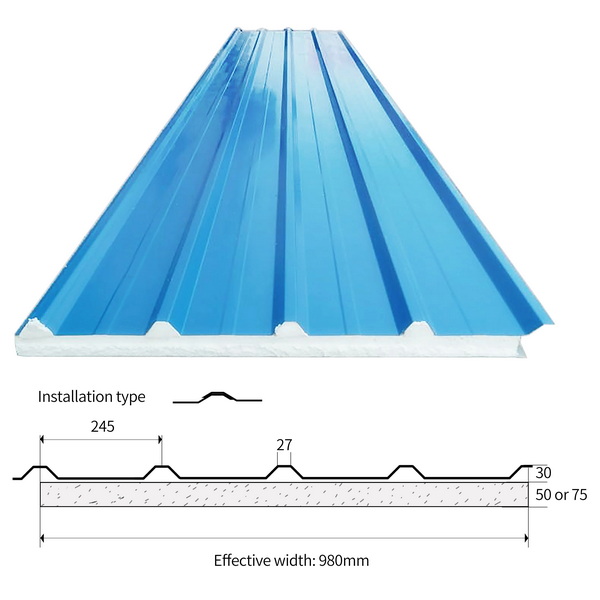

Introduction to Color Steel Sandwich Panels

Color steel sandwich panels are composite building materials consisting of two outer layers of pre-painted color steel sheets bonded to an insulating core. Typical core materials include polyurethane (PU), polyisocyanurate (PIR), mineral wool, and expanded polystyrene (EPS). These cores provide excellent heat retention, fire resistance, and structural support while contributing to overall energy efficiency.

The panels are widely used in industrial facilities, commercial buildings, cold storage warehouses, sports complexes, and cleanrooms. Russian manufacturers and suppliers emphasize production methods and materials suited to the country's demanding climate and regulatory standards, ensuring high-quality and durability.

Leading Russian Manufacturers and Suppliers

Russia's growing infrastructure development and emphasis on energy-efficient construction have driven steady demand for color steel sandwich panels. Prominent Russian manufacturers and suppliers have scaled production capacities and diversified product offerings to meet this need.

Stroypanel LLC

Stroypanel LLC, founded in 1998 and based in St. Petersburg, is one of Russia's leading color steel sandwich panel manufacturers and suppliers. The company specializes in mineral wool core sandwich panels with thicknesses ranging from 50mm to 250mm, suitable for industrial buildings, commercial properties, and multi-use facilities. Stroypanel employs state-of-the-art manufacturing technology to meet stringent fire safety and insulation regulations.

SP-Center

SP-Center is notable for its modern production facilities capable of producing up to 3,000 square meters of roofing and wall panels daily. Using advanced English machinery, their panels are available with EPS and mineral wool cores, customizable up to 16 meters in length and 300mm thickness. The company offers a wide variety of RAL colors and panel profiles, serving diverse construction sectors.

Panelstroy

Panelstroy stands out for its use of innovative cassette profile technology, which reduces steel consumption while delivering durable, lightweight panels. Their range covers thicknesses from 40mm to 200mm with superior UV resistance and mechanical strength, ideal for Russia's variable weather conditions.

Metal-Group LLC

Operating out of Moscow, Metal-Group LLC provides integrated services including steel structure production, insulation, custom cutting, and galvanization. Their sandwich panels, featuring mineral wool or EPS cores, emphasize environmental friendliness by using basalt fiber and eco-friendly materials.

MetalProm LLC

MetalProm LLC has built a reputation for excellence by using premium materials such as SeverStal steel and Rockwool mineral insulation. Their panels comply with national GOST standards and international regulations, ensuring fire resistance, strong adhesion, and durability. Monthly production exceeds 70,000 square meters, demonstrating high capacity and reliability.

Baikal

Baikal is one of the oldest and most recognized brands in Russia, known for PU core panels and decorative finishes mimicking brick, stone, wood, and tile. Baikal prioritizes energy efficiency and environmental sustainability in its designs, which combined with its large-scale production, supply an extensive range of energy-saving sandwich panels throughout Russia and international markets.

Applications and Advantages

Industrial and Commercial Use

Russian color steel sandwich panel manufacturers and suppliers serve a vast range of industries, from logistics centers and industrial parks to agricultural buildings and sports facilities. This wide applicability is due to the panels' excellent thermal insulation, fire resistance, and ease of installation.

Key Benefits

- Thermal and Acoustic Performance: Mineral wool and PIR cores deliver superior thermal insulation, essential for reducing heating costs and improving indoor comfort during Russia's cold winters. Acoustic insulation capabilities also protect against noise pollution in urban environments.

- Fire Safety: Mineral wool-based panels meet high fire-resistance standards, critical for compliance with safety regulations in commercial and industrial buildings.

- Durability and Weather Resistance: High-quality steel facings, coated with advanced protective layers, withstand UV radiation, moisture, and snow loads prevalent across Russia.

- Rapid Installation: Panels are lightweight yet strong, enabling quick assembly and significant labor cost savings for construction projects.

Customization and Design Flexibility

Leading Russian suppliers provide a broad palette of RAL colors and textured finishes for enhanced architectural appeal. Panels can be manufactured with thicknesses from 40mm to 300mm and lengths up to 16 meters. Decorative options—such as wood grain, brick, or stone patterns—enable blending with traditional or modern building aesthetics.

Sustainability Efforts

Sustainability is a growing concern in the Russian sandwich panel industry. Top manufacturers and suppliers adopt eco-conscious approaches by:

- Utilizing recycled steel and environmentally friendly insulation materials.

- Applying energy-efficient production techniques to minimize carbon footprints.

- Offering products designed for prolonged building energy savings.

- Complying with national and international environmental standards and providing Environmental Product Declarations (EPDs) as proof of eco-performance.

Baikal, for example, emphasizes green building through energy-saving panels and environmentally responsible processes that appeal to sustainability-conscious customers.

Advanced Production and Quality Assurance

Russian manufacturers leverage imported European machinery and automation to ensure precision and efficient production cycles. Quality control processes include mechanical testing, thermal performance verification, and fire resistance certification. Such rigorous testing guarantees compliance with Russia's GOST standards and European norms, boosting confidence among investors and builders alike.

Conclusion

The Russian color steel sandwich panel market features a strong mix of established manufacturers and innovative suppliers characterized by broad product customization, adherence to strict quality standards, and sustainability focus. These manufacturers and suppliers provide versatile, durable, and thermally efficient panels suited to Russia's challenging climates and growing construction demands. International OEM partners, including Chinese manufacturers and wholesalers, can greatly benefit from understanding these standards and innovations to enhance competitiveness and successfully collaborate with Russian market players.

FAQ

1. What core materials are mainly used in Russian color steel sandwich panel manufacturing?

Russian manufacturers typically employ mineral wool, polyurethane (PU), and expanded polystyrene (EPS) cores, each selected based on requirements for thermal insulation, fire resistance, or cost-effectiveness.

2. Are customization options available for thickness, length, and finish?

Yes, manufacturers offer thicknesses from 40mm to 300mm, panel lengths up to 16 meters, and a wide range of RAL colors and textured surface finishes, including decorative wood and stone patterns.

3. How do Russian manufacturers ensure compliance with quality and safety standards?

Most manufacturers adhere strictly to Russian GOST standards and international norms. Extensive testing for fire resistance, adhesion, and insulation performance is mandatory before product release.

4. What sustainability initiatives are prioritized in Russia's sandwich panel industry?

Recycling of steel, use of eco-friendly insulation materials, energy-efficient production methods, and developing panels designed to improve building energy consumption are key focus areas, as seen in leading suppliers like Baika.

5. Which sectors commonly utilize color steel sandwich panels in Russia?

Key industries include industrial construction, logistics warehouses, cold storages, agriculture, retail, public buildings, sports complexes, and increasingly, residential applications demanding fast and energy-efficient construction.