Content Menu

● Introduction to Color Steel Sandwich Panels

● Leading Spanish Manufacturers and Suppliers

>> Hiansa

>> Panelfa

>> Magón

>> Panelwork

>> Assan Panel (International Influence)

● Market Trends and Dynamics

● Applications and Benefits of Color Steel Sandwich Panels

>> Thermal Efficiency and Energy Savings

>> Weather and Fire Resistance

>> Aesthetic and Functional Versatility

>> Fast and Versatile Installation

● Sustainability Commitment in Spain

● Enhanced Durability and Innovation

● Production Techniques and Quality Assurance

● Conclusion

● FAQ

>> 1. What types of insulation cores do Spanish color steel sandwich panel manufacturers offer?

>> 2. Can customers customize panel dimensions, colors, and finishes in Spain?

>> 3. How do Spanish sandwich panels meet environmental and energy standards?

>> 4. Which industries frequently use color steel sandwich panels in Spain?

>> 5. What after-sales services do Spanish suppliers typically provide?

Color steel sandwich panels have emerged as vital components in Spain's construction sector, offering exceptional thermal insulation, durability, design flexibility, and ease of installation. For international brands, wholesalers, and manufacturers seeking OEM partners, understanding Spain's leading color steel sandwich panel manufacturers and suppliers is key to navigating this dynamic market. This comprehensive article explores the top players, industry innovations, market trends, and practical applications shaping the color steel sandwich panel landscape across Spain.

Introduction to Color Steel Sandwich Panels

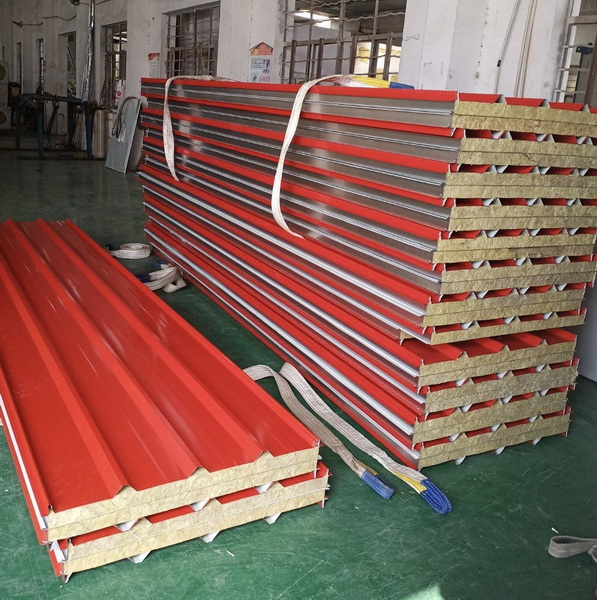

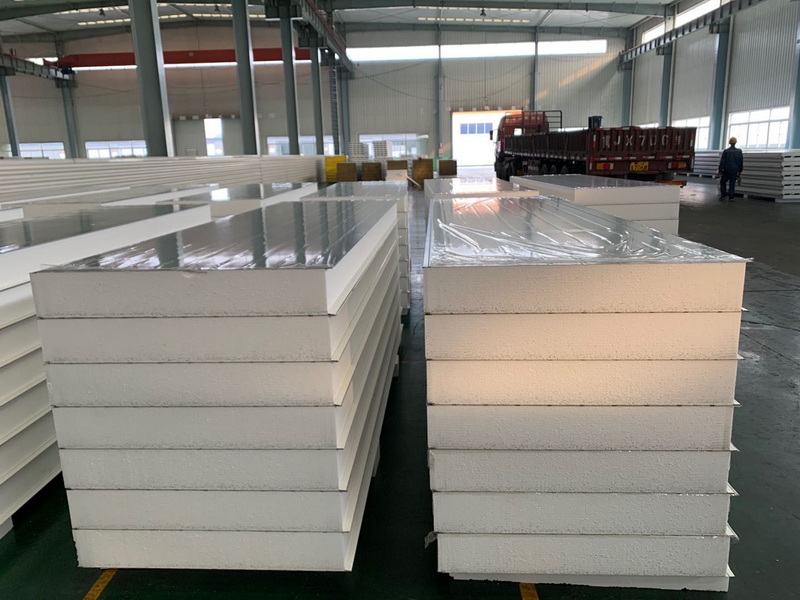

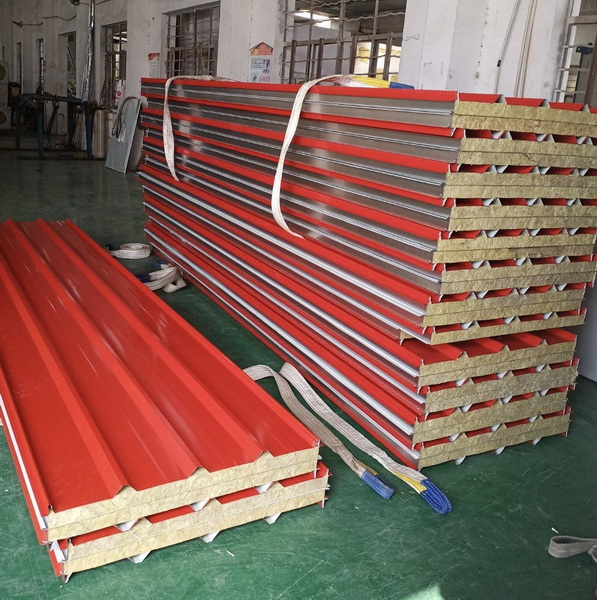

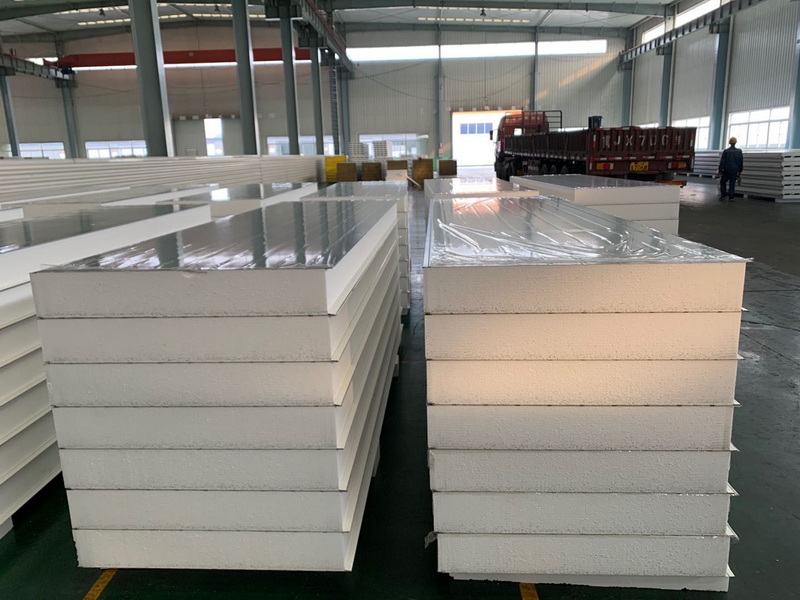

Color steel sandwich panels are composite building materials consisting of two outer layers of pre-painted steel sheets bonded to an insulating core. Common cores include polyurethane (PU), polyisocyanurate (PIR), mineral wool, and expanded polystyrene (EPS). The panels combine excellent thermal performance, weather resistance, fire safety, mechanical strength, and aesthetic appeal, making them ideal for commercial, industrial, agricultural, and residential construction.

Spanish manufacturers and suppliers emphasize manufacturing precision, sustainability, and wide customization options to cater to evolving client demands and regulatory standards.

Leading Spanish Manufacturers and Suppliers

Spain's construction growth and increasing attention to energy-efficient building materials have helped many sandwich panel producers expand their offerings and capabilities. Notable manufacturers and suppliers in Spain include:

Hiansa

With over 40 years of experience, Hiansa is a major manufacturer and supplier of color steel sandwich panels in Spain. They produce panels tailored for roofs, facades, and cold storage with a focus on quality and innovation. Their extensive catalog covers various insulation cores—polyurethane, mineral wool, etc.—and features multiple coating and finish options to meet architectural and thermal specifications. Hiansa is part of the Association of Spanish Sandwich Panel Manufacturers, highlighting its industry leadership.

Panelfa

Panelfa specializes in high-production sandwich panel manufacturing with a capacity exceeding 300,000 square meters annually. Located in Spain, Panelfa offers wall and roof panels tested rigorously for safety, durability, and energy performance. Their product lines include panels suited for industrial construction, commercial premises, and eco-conscious buildings, with customizable thickness and colors.

Magón

Magón focuses on manufacturing sandwich roof panels and related building materials with polyurethane core insulation. Their products are designed for both interior and exterior applications, providing thermal insulation, structural integrity, and resistance to weather conditions. Magón's sandwich panels comply with high quality standards, delivering economical and effective building solutions.

Panelwork

Panelwork provides interior design-oriented sandwich panels, including acoustic and decorative 3D panels, focusing on quality finishes and customization. Though oriented toward interiors, their products enrich commercial and residential spaces with stylish cladding and soundproofing solutions.

Assan Panel (International Influence)

Although based in Turkey, Assan Panel has a significant footprint in the Spanish market through distribution and partnerships. They are renowned for environmentally friendly, colorful, durable sandwich panels tailored for roofs, walls, and cold stores. Their innovative panel designs emphasize energy efficiency and rapid installation with customizable aesthetics.

Market Trends and Dynamics

Spain's construction market increasingly favors sustainable and energy-efficient materials, driving growth in color steel sandwich panel use. Government incentives for green buildings combined with accelerating urban and industrial development expand the demand for high-performance panels.

- The emphasis on reduced carbon footprints and enhanced insulation is steering manufacturers toward advanced cores like PIR and mineral wool, roles historically dominated by polyurethane and EPS.

- Cross-sector usage is rising, spanning commercial warehouses, cold chain logistics, agricultural buildings, sports and recreational facilities, and modular housing.

- Manufacturers invest in automation and precision coating technologies to maintain competitive pricing without compromising quality.

Applications and Benefits of Color Steel Sandwich Panels

Thermal Efficiency and Energy Savings

Sandwich panels provide exceptional insulation, helping reduce energy costs for heating and cooling by meeting or exceeding Spain's thermal building regulations. Mineral wool and PIR cores especially contribute to improved U-values and fire resistance.

Weather and Fire Resistance

The pre-painted steel exterior protects against corrosion, UV radiation, and environmental wear, while mineral wool cores provide fire resistance, critical for safety compliance in public and industrial buildings.

Aesthetic and Functional Versatility

Spanish manufacturers enable a variety of finishes, colors from the RAL palette, and textures—ranging from smooth metallic to wood or stone-like surfaces. Such options help architects create distinctive facades while maintaining panel functionality.

Fast and Versatile Installation

Modular and lightweight, color steel sandwich panels reduce site labor and accelerate construction timelines, a key factor in Spain's fast-paced building environments.

Sustainability Commitment in Spain

Spanish manufacturers take sustainability seriously by:

- Producing panels with recycled steel and environmentally certified paints.

- Offering low-VOC coatings and using formaldehyde-free insulation cores.

- Developing energy-efficient panels that help achieve certifications such as LEED and BREEAM.

- Implementing waste reduction and efficient manufacturing methods aligning with EU environmental directives.

Enhanced Durability and Innovation

Spanish suppliers continually innovate to enhance panel durability and functionality:

- Advanced Coatings: Utilization of fluoropolymer paints and anti-corrosive treatments ensures panels withstand harsh weather and resist fading.

- Fire Safety Innovations: Use of mineral wool and PIR cores enhances fire resistance, ensuring compliance with increasingly strict building codes.

- Acoustic Performance: Acoustic sandwich panels reduce noise pollution, especially useful in urban residential and commercial projects.

- Integrated Systems: Some manufacturers integrate vapor barriers, anti-condensation layers, and other functional components to improve building envelope performance.

Production Techniques and Quality Assurance

Leading Spanish manufacturers employ automated roll forming, lamination, and cutting technologies for precision manufacturing. Quality assurance includes rigorous testing for mechanical strength, thermal performance, fire resistance, and coating durability. Compliance with ISO standards and European building regulations reflects their commitment to high quality.

Conclusion

Spain's color steel sandwich panel manufacturers and suppliers stand at the intersection of quality, innovation, and sustainability. Their broad product range, extensive customization options, and commitment to eco-friendly practices meet the diverse needs of modern construction. For international OEM partners—including Chinese scaffolding material manufacturers—collaborating with Spain's industry leaders offers opportunities to integrate premium panels into global building solutions, enhancing competitiveness and fostering growth.

FAQ

1. What types of insulation cores do Spanish color steel sandwich panel manufacturers offer?

Common cores include polyurethane (PU), polyisocyanurate (PIR), mineral wool, and expanded polystyrene (EPS), each balancing cost, thermal performance, and fire resistance.

2. Can customers customize panel dimensions, colors, and finishes in Spain?

Yes, most manufacturers provide customized lengths, thicknesses (typically 40mm to 250mm), a broad spectrum of RAL colors, and various surface textures to suit design requirements.

3. How do Spanish sandwich panels meet environmental and energy standards?

Manufacturers comply with EU building codes promoting energy efficiency, use eco-friendly materials, and produce panels certified under LEED, BREEAM, or Spanish national standards.

4. Which industries frequently use color steel sandwich panels in Spain?

Applications include industrial warehouses, cold chain logistics, agricultural buildings, commercial centers, sports venues, and increasingly energy-efficient residential housing.

5. What after-sales services do Spanish suppliers typically provide?

Services often include technical consultation, installation assistance, warranty and maintenance support, and rapid response to client needs or custom requirements.