What Are Scaffolding Boards

Scaffolding boards, also known as scaffold planks or walk boards, are essential components of scaffolding systems used in construction. They provide a stable platform for workers to walk, transfer materials, and perform various tasks at height. These boards are temporary and reusable, making them a crucial part of any construction project. Let's delve into the details of what scaffolding boards are, their types, their applications, advantages and disadvantages.

Types of Scaffolding Boards

1. Wooden Scaffolding Boards

Material: Made from wood, typically pine or fir. An alternative material to traditional wood boards is laminated veneer lumber (LVL), which consists of multiple layers of thin wood assembled with adhesives.

Applications: Commonly used in bamboo, wooden, tube and coupler scaffolding, and tubular frame scaffolding systems. They are a good option for use by scaffold manufacturing companies and professional contractors in the masonry, plastering, and stucco industries.

Specifications: Board thickness should be at least 50 mm, width between 200-250 mm, and length between 3-6 meters. To prevent damage, the ends are often reinforced with iron wire or metal strips.

Characteristics: Widely used, cost-effective, easy to install and remove, with exceptional stability and durability. They provide good foot traction. However, their use is declining due to environmental concerns and limited availability of wood.

Market: The United States, Peru, India, the United Kingdom (UK), Germany are major importers and users of wooden scaffolding boards. Ireland in Europe, Chile in America, Malaysia, Japan, Singapore, Philippines in Asia, United Arab Emirates (UAE), and New Zealand are the countries that also use wooden planks.

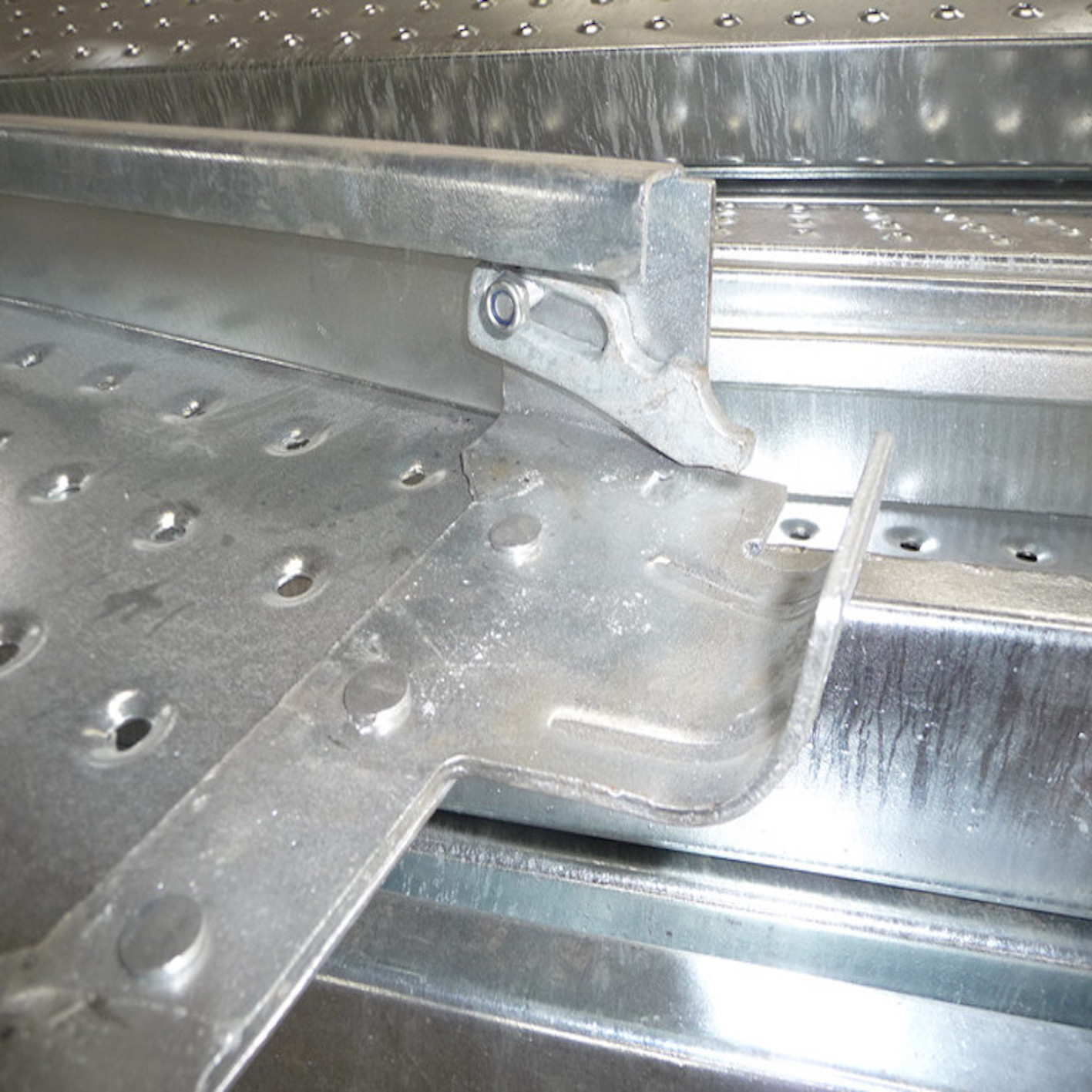

2. Steel Scaffolding Boards

Material: Typically made from high-strength C profile steel, steel grade Q235 or S235, which is often hot-dip galvanized to prevent rust and corrosion. Designed to withstand heavy loads on a construction site. Sometimes made by Q195 steel grade, pre-galvanized steel, offering a cost-effective choice.

Applications: Used in various scaffolding systems, including tube and coupler scaffold, ringlock system scaffold, cuplock system scaffold, kwikstage system scaffold, etc.

Specifications: Various sizes and weights, with hook or without hooks.

Planks for Tube and Coupler Scaffold: Width: 210mm, 225mm, 240mm, 480mm, etc. Length: 1m, 1.5m, 2m, 2.5m, 3m, 4m, etc. Thickness varies from 1.1mm to 2mm. Pre-galvanized steel is used a lot. These metal scaffolding planks are mostly made without hooks. Scaffold board clamps, also called board retaining couplers, are used to hold and connect these planks.

Planks for Ringlock Scaffolding: Width: 228mm (9”) or 240mm (9.5”). Length: ranges from 0.73m to 3.07m, always compatible with scaffolding system. Thickness of the steel ranges from 1.5mm-2mm. These planks are made with hooks. Surface finish: HDG or pre-galvanized steel.

Planks for Layher All Round Scaffolding: Width: 190mm or 320mm. Length: ranges from 0.73m to 3.07m, always compatible with scaffolding system. Thickness of the steel ranges from 1.5mm-2mm. These planks are made with hooks. There are two different types of hooks, which can fit with O-type ledgers and U-type ledgers. Surface finish: HDG.

Planks for Cuplock Scaffolding: Width: 228mm (9”). Length: 3’-10’, matches with the Cuplock Ledger Axial Size, always compatible with scaffolding system. Thickness of the steel ranges from 1.5mm-2mm. These planks are made with hooks. Surface finish: HDG.

Planks for Kwikstage Scaffolding: Width: 240mm (9.5”). Length: 0.7-2.4m, always compatible with scaffolding system. Thickness of the steel ranges from 1.5mm-2mm. These planks are made without hooks. They sit on the kwikstage scaffolding transoms. Surface finish: Pre-galvanized steel is more commonly used.

Characteristics: Steel planks are durable and can withstand harsh weather conditions. They can support heavier loads. Steel planks cannot absorb moisture, offering good moisture resistance. They are fire-resistant. An anti-slip surface increases the safety of scaffolding planks. Locking pins are used to secure the plank onto the scaffold, providing resistance against wind forces.

Market: The market for scaffolding steel planks is global, encompassing any location where tube and coupler scaffolding or system scaffolding is utilized.

Material:

1. All aluminum, offering lightweight and high strength.

2. Aluminum and plywood, offering light weight, high strength, and cost-effectiveness.

Applications: Used in various scaffolding systems, including frame scaffolding and system scaffolding, such as ringlock system and cuplock system.

Specifications: Various sizes, including 19" and 19.25" widths, and customizable lengths from 3’6” to 10’, in which 7’ and 10’ boards are the most popular. For aluminum and plywood decks, the width is 19”. For aluminum and plywood decks with trapdoor and ladders, the width is 610mm, length to be custom.

Characteristics: Lightweight, durable, and corrosion-resistant, making these aluminum planks ideal for modern construction projects.

Market: Canada and the United States are the countries where aluminum scaffolding planks and aluminum-wood composite planks are most commonly used.

Advantages and Disadvantages of Different Types of Scaffolding Planks

Wooden Boards

Advantages:

Wooden scaffolding planks have a relatively simple production process and are relatively inexpensive, making them a cost-effective option.

They are lightweight, easy to install, dismantle, and transport.

Disadvantages:

Maintenance costs are relatively high, requiring frequent inspections and repairs.

They are susceptible to different environmental climates and are not suitable for long-term outdoor use.

They may absorb moisture or humidity, increasing the product weight and accelerating corrosion.

They cannot fully guarantee fire resistance.

Without the locking mechanisms found in steel or aluminum planks, their safety is compromised.

Steel Scaffolding Planks

Advantages:

Steel scaffolding planks are made from high-quality structural steel, offering higher load-bearing capacity and the ability to handle more complex construction tasks.

They perform better than wooden planks in terms of water absorption and fire resistance.

Hot-dip galvanized planks have a long service life.

Disadvantages:

Steel planks are heavier, making them more difficult to transport and install compared to wooden planks.

The production process is more complex and costly, resulting in a higher price than wooden planks.

Aluminum Planks

Advantages:

Aluminum scaffolding planks are lighter than wooden and steel planks, making them easier to handle during construction and more efficient to transport.

They have high load-bearing capacity, excellent safety features, and can withstand various extreme weather conditions.

They are superior to wooden and steel planks in terms of rust resistance and resistance to corrosive substances, offering the longest service life.

Disadvantages:

Aluminum material is more expensive than wood or steel, making it the most costly option among the three types of scaffolding planks.

However, its longer service life makes it a worthwhile investment.

By understanding these advantages and disadvantages, construction professionals can make informed decisions about which type of scaffolding plank best suits their specific needs and budget.

Conclusion

Scaffolding boards are indispensable equipment in the construction industry, providing a safe and stable platform for workers. With various types available, each suited to different applications, choosing the right scaffolding board is crucial for the success and safety of any construction project. Whether you are working on a residential building, a commercial structure, or a specialized project, understanding the different types and their features will help you make an informed decision. Tuopeng Scaffold is a company engaged in supplying and exporting all types of scaffolding equipment, including the above-introduced three types of scaffolding boards. If you need to buy scaffolding boards for decking, contact us for the latest prices via info@tp-scaffold.com.