Content Menu

● Modular Design

● Versatility and Adaptability

● Safety and Stability

● Speed and Efficiency

● Durability

● Cost-Efficiency

● Types of System Scaffolding

● Environmental Considerations

● Technological Integration

● Training and Competence

● Case Studies

● Conclusion

● FAQ

>> 1. What is system scaffolding?

>> 2. How does system scaffolding differ from traditional scaffolding?

>> 3. What are the safety features of system scaffolding?

>> 4. Can system scaffolding be used for all types of construction projects?

>> 5. What are the cost benefits associated with using system scaffolding?

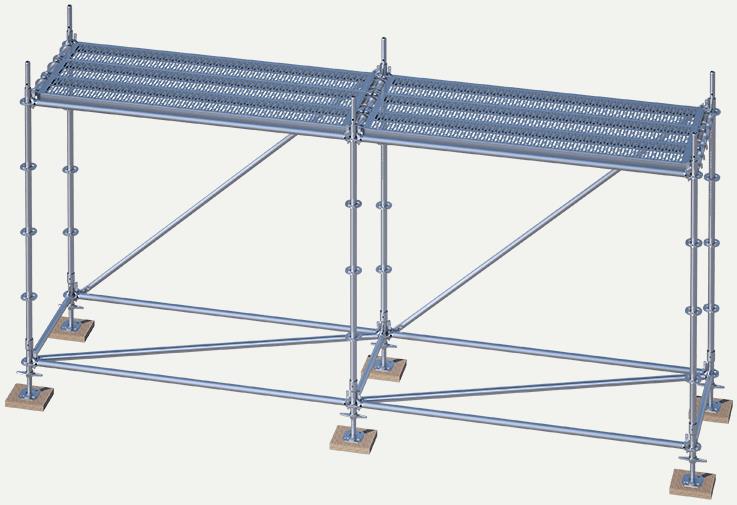

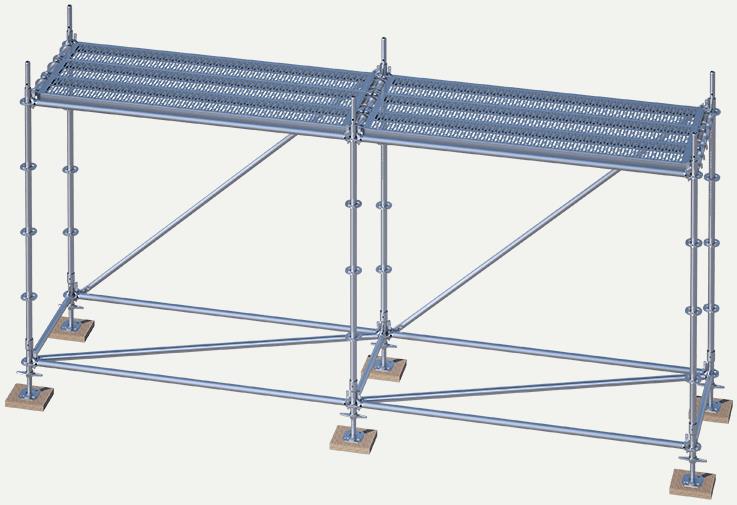

System scaffolding, also known as modular scaffolding, has become a cornerstone in construction and engineering due to its efficiency, safety, and adaptability. This article explores the defining characteristics of system scaffolding, highlighting its advantages and applications in modern construction practices.

Modular Design

One of the most significant characteristics of system scaffolding is its modular design. Unlike traditional scaffolding systems that often rely on custom-built components, system scaffolding utilizes standardized parts. This modular approach allows for rapid assembly and disassembly, significantly reducing setup time and labor costs.

- Transportability: Modular components can be easily transported, stored, and reused across different projects, enhancing sustainability.

- Maintenance: Damaged parts can be quickly replaced without disrupting the entire structure, making maintenance straightforward.

The modular design also allows for easy customization. Construction teams can select specific components based on the project's requirements, ensuring that the scaffold meets safety standards while providing adequate support for workers and materials.

Versatility and Adaptability

System scaffolding is renowned for its versatility and adaptability. It can be configured to meet the unique requirements of various construction sites, whether it's a high-rise building, a bridge, or a tunnel.

- Custom Configurations: The modular components can be combined in various ways to create custom scaffolds tailored to specific project needs.

- Progressive Adjustments: As construction progresses, system scaffolding can be adjusted seamlessly to accommodate changes in height, width, and configuration.

This adaptability makes system scaffolding suitable for both small-scale residential projects and large infrastructure developments. For instance, in a high-rise construction project, the scaffold can be extended vertically as the building rises, ensuring that workers have safe access at all levels.

Safety and Stability

Safety is paramount in construction, and system scaffolding excels in this area. The systems are designed to be robust, with secure connections that minimize the risk of slippage or dislodgment.

- Enhanced Safety Features: The uniformity of components reduces human error during assembly, ensuring that all parts fit together securely.

- Fall Prevention: Many system scaffolds incorporate fall prevention methodologies that enhance worker safety on site.

Moreover, system scaffolding often includes guardrails and toe boards to prevent tools and materials from falling off the edges. These safety features are critical in high-altitude work scenarios where falls can result in severe injuries or fatalities.

Speed and Efficiency

One of the primary advantages of system scaffolding is its quick assembly and disassembly. The modular nature allows for rapid construction, which is particularly beneficial in projects with tight schedules.

- Reduced Labor Costs: Faster setup times mean fewer labor hours are required on-site, translating into significant cost savings.

- Streamlined Operations: The efficiency of assembly processes allows contractors to complete projects ahead of schedule.

In addition to saving time during initial setup, system scaffolding also facilitates quick adjustments throughout the project lifecycle. If changes need to be made due to design modifications or unforeseen challenges, workers can easily reconfigure the scaffold without extensive downtime.

Durability

System scaffolding components are typically made from high-quality materials such as steel or aluminum. This durability ensures that they can withstand harsh weather conditions and heavy loads.

- Long Lifespan: The robust nature of these materials means that they can be used across multiple projects without significant wear and tear.

- Resistance to Elements: System scaffolding can be utilized in various environments, from coastal areas with high salinity to industrial sites exposed to chemicals.

The durability of system scaffolding not only contributes to safety but also enhances overall project efficiency. By reducing the need for frequent replacements or repairs, contractors can focus resources on other critical aspects of construction.

Cost-Efficiency

Cost-efficiency is a significant advantage of system scaffolding. The modular design and reusability of components contribute to lower overall costs compared to traditional scaffolding methods.

- Lower Setup Costs: The reduced setup time leads to savings on both time and money.

- Long-Term Investment: The durability of system scaffolding components ensures they can be reused across multiple projects, enhancing their cost-effectiveness over time.

Additionally, many companies find that investing in a quality system scaffold pays off through reduced insurance premiums due to enhanced safety records. Fewer accidents lead to lower liability costs and better overall project management.

Types of System Scaffolding

There are several popular types of system scaffolding used in the industry today:

| Type | Description |

|--------------|-------------|

| Ringlock | Features a central connector with multiple openings allowing for multiple connections at various angles. |

| Cuplock | Utilizes a node point where horizontal components can be connected securely. |

| Kwikstage | Known for its wedge fixing method that locks horizontal ledgers to vertical standards. |

| OCTO® | Offers superior strength and flexibility with fewer components required for setup. |

Each type has its unique features but generally offers similar benefits in terms of flexibility, safety, and adaptability. Understanding these types helps contractors select the best option based on specific project requirements.

Environmental Considerations

As sustainability becomes increasingly important in construction practices, system scaffolding stands out due to its environmental benefits:

- Reusability: Components can be reused across multiple projects rather than being discarded after one use.

- Reduced Waste: The modular nature minimizes material waste during installation since only necessary parts are used for each job.

Many companies are now prioritizing eco-friendly practices by choosing materials that are recyclable at the end of their lifecycle. This commitment not only helps reduce environmental impact but also enhances corporate responsibility profiles.

Technological Integration

The integration of technology into system scaffolding has revolutionized its application:

- Digital Planning Tools: Advanced software allows engineers to design complex scaffold structures virtually before actual assembly begins. This minimizes errors during construction and maximizes efficiency on-site.

- Smart Monitoring Systems: Some modern systems include sensors that monitor load distribution and structural integrity in real-time. This technology provides immediate feedback on safety conditions during use.

By leveraging technology, contractors can further enhance safety protocols while optimizing resource allocation throughout the project lifecycle.

Training and Competence

While system scaffolding offers numerous advantages, proper training is essential for maximizing its benefits:

- Skilled Labor Requirements: Workers must understand how to assemble and disassemble various types correctly while adhering to safety protocols.

- Certification Programs: Many organizations offer certification programs focused on best practices for using system scaffolding effectively. These programs ensure that workers are competent in their roles while promoting a culture of safety on-site.

Investing in training not only improves worker confidence but also reduces the likelihood of accidents caused by improper use or assembly techniques.

Case Studies

Several successful projects illustrate the effectiveness of system scaffolding:

- High-Rise Construction: A recent skyscraper project utilized ringlock scaffolding for its ability to adapt as floors were added. The project was completed two months ahead of schedule due to efficient scaffold installation processes.

- Bridge Renovation: During a bridge renovation project, cuplock scaffolding provided stable access for workers while minimizing disruption to traffic below. The modular design allowed for quick adjustments as work progressed without compromising safety or efficiency.

These case studies highlight how various industries benefit from adopting system scaffolding solutions tailored specifically for their needs.

Conclusion

In conclusion, system scaffolding is characterized by its modular design, versatility, safety features, speed of assembly, durability, cost-efficiency, environmental considerations, technological integration, training requirements, and successful case studies. These characteristics make it an invaluable asset in modern construction practices. By providing a stable and adaptable support structure, system scaffolding facilitates complex building projects while optimizing time and resources. As the construction industry continues to evolve towards more efficient practices, the importance of utilizing effective scaffolding systems will undoubtedly grow.

FAQ

1. What is system scaffolding?

System scaffolding is a type of scaffold made up of pre-engineered modular components that connect securely without the need for traditional fittings. It allows for quick assembly and disassembly while providing a safe working environment.

2. How does system scaffolding differ from traditional scaffolding?

Unlike traditional tube-and-coupler scaffolding that relies on many individual parts and fittings, system scaffolding uses standardized modules that interlock easily, leading to faster setup times and reduced complexity.

3. What are the safety features of system scaffolding?

System scaffolding includes secure locking mechanisms that minimize slippage risks during assembly. Additionally, many designs incorporate fall prevention features to enhance worker safety on site.

4. Can system scaffolding be used for all types of construction projects?

Yes! System scaffolding is versatile enough to be adapted for various construction types including residential buildings, commercial structures, bridges, and industrial installations.

5. What are the cost benefits associated with using system scaffolding?

The quick assembly reduces labor costs significantly while the durability allows for reuse across multiple projects. This long-term investment leads to substantial savings over time compared to traditional methods.