Content Menu

● Introduction to A Frame Scaffolding

● Modular Design and Components

● Key Dimensions in A Frame Scaffolding Specifications

>> Frame Width and Height

>> Platform Dimensions

>> Load Capacity

>> Cross Braces and Screw Jacks

● Importance of Correct Dimensions

>> Safety Considerations

>> Efficiency and Productivity

● A Frame Scaffolding Specifications Around the World

>> Australian Standards

>> European and American Standards

● Conclusion

● FAQ

>> 1. What are the typical widths of A frame scaffolding?

>> 2. How is the height of A frame scaffolding adjusted?

>> 3. What is the load capacity of standard A frame scaffolding?

>> 4. Why is modular design important in A frame scaffolding?

>> 5. What safety features should A frame scaffolding include?

● Citations:

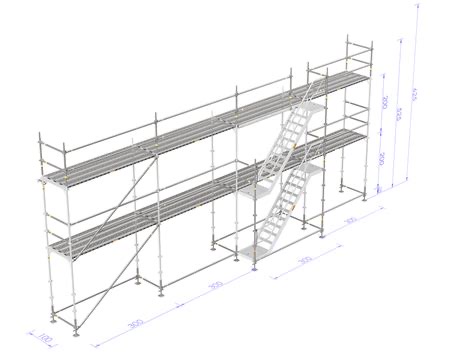

A frame scaffolding is a crucial tool in construction and maintenance projects, providing a safe and stable platform for workers to perform tasks at heights. Understanding the key dimensions in A frame scaffolding specifications is essential for ensuring safety, efficiency, and compliance with regulatory standards. This article will delve into the critical dimensions and components of A frame scaffolding, highlighting their importance and how they contribute to the overall functionality of the scaffold.

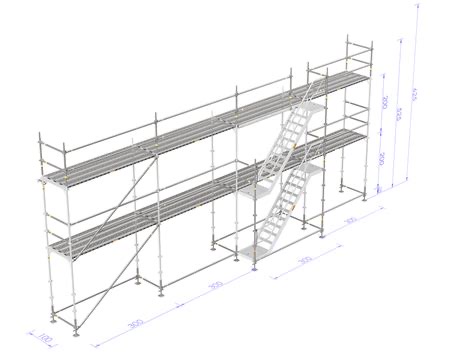

Introduction to A Frame Scaffolding

A frame scaffolding is characterized by its A-shaped structure, which is composed of steel frames and cross braces. These components work together to create a robust framework that supports elevated platforms, allowing workers to access challenging areas safely. The modular design of A frame scaffolding makes it versatile and adaptable for various applications, from residential projects to large-scale commercial construction sites.

Modular Design and Components

The modular nature of A frame scaffolding allows it to be easily assembled and disassembled, making it ideal for projects that require frequent adjustments or relocation. The primary components include:

- Steel Frames: These are the main structural elements, providing the A shape that gives the scaffold its name.

- Cross Braces: These add stability to the structure by connecting the frames.

- Platform Planks: These are the surfaces on which workers stand.

- Screw Jacks: Used to adjust the height and level of the scaffold.

Key Dimensions in A Frame Scaffolding Specifications

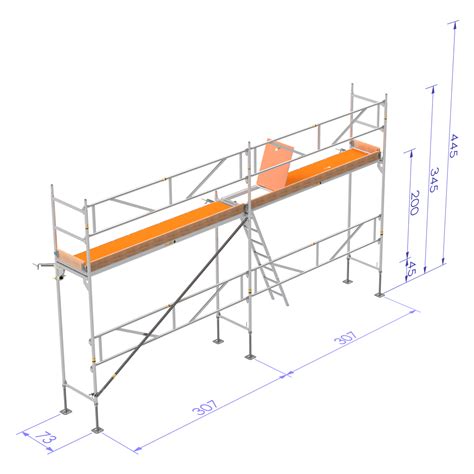

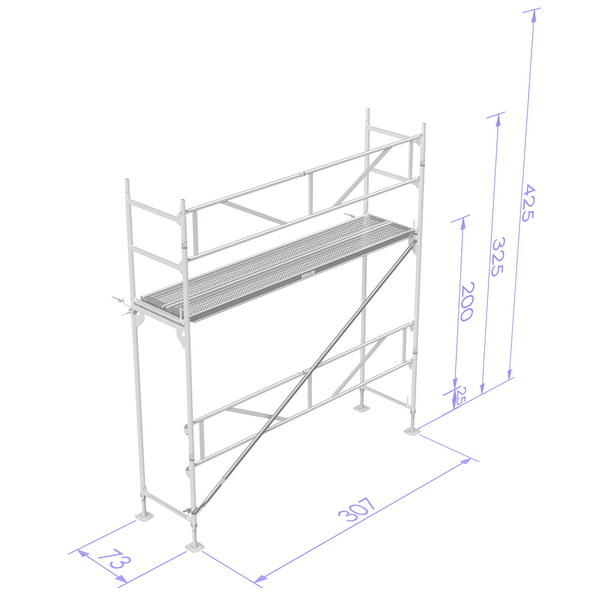

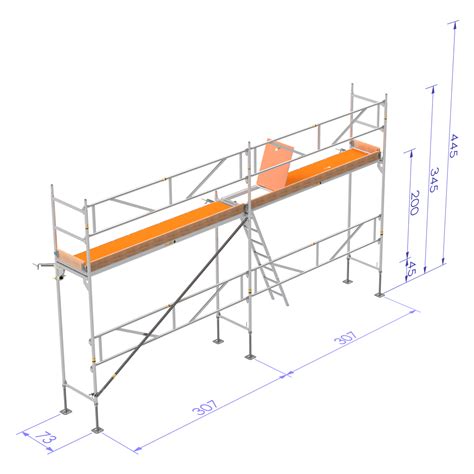

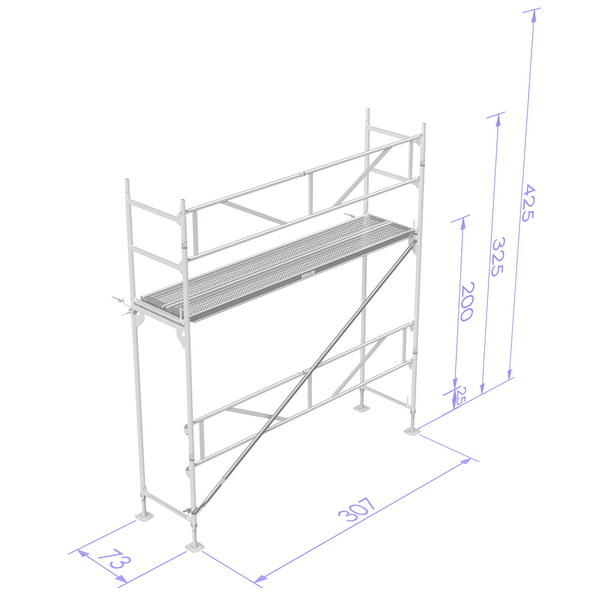

Understanding the dimensions of A frame scaffolding is crucial for selecting the right equipment for a project. Here are some key dimensions to consider:

Frame Width and Height

- Width: The width of A frame scaffolding can vary significantly, with common widths including 780 mm for narrow frames and 1225 mm for wider frames[1][7].

- Height: The height of the scaffold can be adjusted using screw jacks, but standard frame heights often range from 1.5 meters to 2 meters or more, depending on the application[1][7].

Platform Dimensions

- Platform Length: Typically, platform planks are around 1.8 meters long, providing ample space for workers to move around[1].

- Platform Width: This depends on the width of the frame but is usually designed to fit snugly within the frame structure.

Load Capacity

- Load Rating: A frame scaffolding is designed to handle significant loads, often up to 675 kg, ensuring that it can support multiple workers and their equipment safely[1][7].

Cross Braces and Screw Jacks

- Cross Brace Length: These are typically longer than the frame height to ensure stability, often around 2.1 meters[1].

- Screw Jack Height Adjustment: Allows for precise leveling and height adjustments to ensure the scaffold is stable on uneven surfaces.

Importance of Correct Dimensions

Using scaffolding with the correct dimensions is vital for safety and efficiency. Incorrectly sized scaffolding can lead to instability, reduced workspace, or even accidents. For instance, a scaffold that is too narrow may not provide enough working space, while one that is too wide may be cumbersome in tight spaces.

Safety Considerations

Safety is paramount when working at heights. Properly sized scaffolding ensures that guardrails can be installed correctly, preventing falls and providing a secure working environment. Regulatory guidelines, such as those from WorkSafe, emphasize the importance of using scaffolding that meets specific safety standards[7].

Efficiency and Productivity

The right dimensions can significantly enhance productivity. For example, wider platforms allow more workers to work simultaneously, reducing project timelines. Additionally, modular designs enable quick assembly and disassembly, saving time and resources.

A Frame Scaffolding Specifications Around the World

A frame scaffolding specifications can vary slightly depending on regional standards and regulations. For instance, Australian standards (AS/NZS) specify different frame sizes and weights, reflecting local building practices and safety requirements[4].

Australian Standards

- Frame Sizes: Common sizes include 1310 mm wide for standard frames and 780 mm for narrow frames[4].

- Weight and Load Capacity: These are also specified to ensure compliance with local safety regulations.

European and American Standards

While specific standards may differ, the core principles of A frame scaffolding remain consistent across regions. The emphasis is always on safety, durability, and adaptability to various construction environments.

Conclusion

A frame scaffolding specifications are critical for ensuring the safety and efficiency of construction projects. By understanding the key dimensions and components, users can select the appropriate scaffolding for their needs, comply with regulatory standards, and enhance productivity. Whether for residential repairs or large-scale commercial projects, A frame scaffolding remains a versatile and essential tool in the construction industry.

FAQ

1. What are the typical widths of A frame scaffolding?

A frame scaffolding typically comes in widths of 780 mm for narrow frames and 1225 mm for wider frames[1][7].

2. How is the height of A frame scaffolding adjusted?

The height of A frame scaffolding is adjusted using screw jacks, which allow for precise leveling and height adjustments[1].

3. What is the load capacity of standard A frame scaffolding?

Standard A frame scaffolding is designed to handle loads up to 675 kg, ensuring it can support multiple workers and equipment safely[1][7].

4. Why is modular design important in A frame scaffolding?

The modular design makes A frame scaffolding versatile and easy to assemble/disassemble, ideal for projects requiring frequent adjustments or relocation[1][7].

5. What safety features should A frame scaffolding include?

A frame scaffolding should include guardrails on all sides to prevent falls and ensure a secure working environment[6].

Citations:

[1] https://estnmetal.com/product/1-5m-a-frame-scaffold-wide/

[2] https://www.istockphoto.com/photos/frame-scaffolding

[3] https://blog.csdn.net/weixin_40289064/article/details/79669930

[4] https://www.gzshuangma.com/as-nzs-australian-a-frame-scaffolding_p44.html

[5] https://www.istockphoto.com/photos/scaffold-frame

[6] https://www.safework.nsw.gov.au/resource-library/scaffolding/erecting,-altering-and-dismantling-scaffolding-part-1-prefabricated-steel-modular-scaffolding

[7] https://www.scafeast.com/products/1-5m-a-frame-scaffold-single-width/

[8] https://www.youtube.com/watch?v=Iqx-9zIpRFU

[9] https://www.sohu.com/a/372324657_770312

[10] https://www.nordscaffolding.com/product/frame-scaffolding-tower/

[11] https://www.youtube.com/watch?v=ZYzbjPRzI6Q

[12] https://www.w3.org/TR/clreq/

[13] https://tswufang.en.made-in-china.com/product/oOyTqsrGAHYi/China-6-prime-7-Walk-Thru-Scaffold-Frame-a-Arch-Frame-Scaffolding-42mm-Dimension.html

[14] https://www.labour.gov.hk/eng/public/pdf/os/D/TOS_Guidance_notes_eng.pdf