Content Menu

● Introduction to Cuplock Scaffolding

● Components of Cuplock Scaffolding

● Cuplock Scaffolding Specifications

>> Material Specifications

>> Dimensional Specifications

>> Load Capacity

>> Assembly and Safety

● Applications of Cuplock Scaffolding

● Safety Considerations

● Assembly Process

● Detailed Assembly Steps

● Advanced Applications

● Customization Options

● Environmental Considerations

● Training and Certification

● Conclusion

● FAQ

>> 1. What are the main components of cuplock scaffolding?

>> 2. What is the typical material used for cuplock scaffolding?

>> 3. How is cuplock scaffolding assembled?

>> 4. What are the common applications of cuplock scaffolding?

>> 5. What safety considerations should be taken into account?

● Citations:

Cuplock scaffolding is a widely used system in the construction industry due to its reliability, safety, and ease of assembly. It is composed of various components such as standards, ledgers, braces, and planks, all connected through a unique cup-node locking mechanism. This article will delve into the standard specifications of cuplock scaffolding, its components, applications, and safety considerations.

Introduction to Cuplock Scaffolding

Cuplock scaffolding is known for its modular design, which allows it to be easily erected and dismantled. The system consists of vertical standards and horizontal ledgers connected by cups, eliminating the need for loose pins or bolts. This makes it a preferred choice for construction projects requiring rapid setup and teardown.

Components of Cuplock Scaffolding

- Standards: These are the vertical tubes that provide the main support structure. They are typically made from 48.3mm diameter pipes with a thickness of 3.2mm, often in S355 steel grade.

- Ledgers: These are the horizontal tubes that connect between standards. They also use 48.3mm diameter pipes with a thickness of 3.2mm.

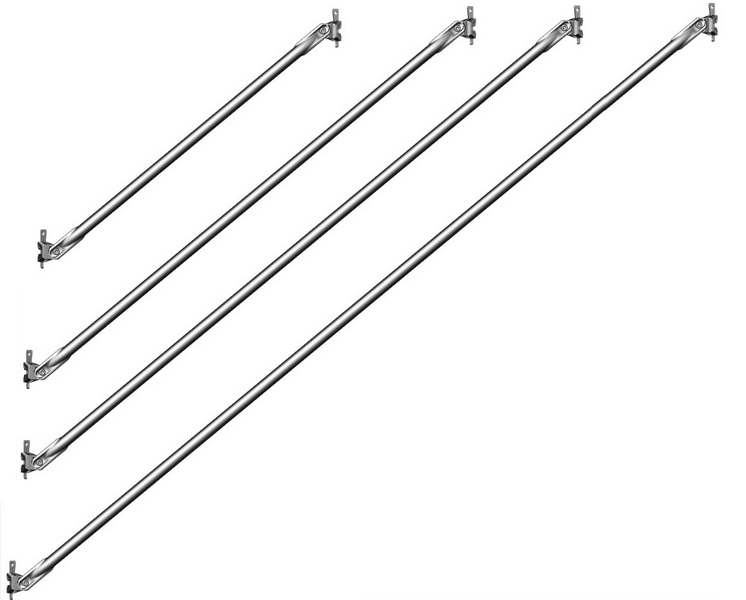

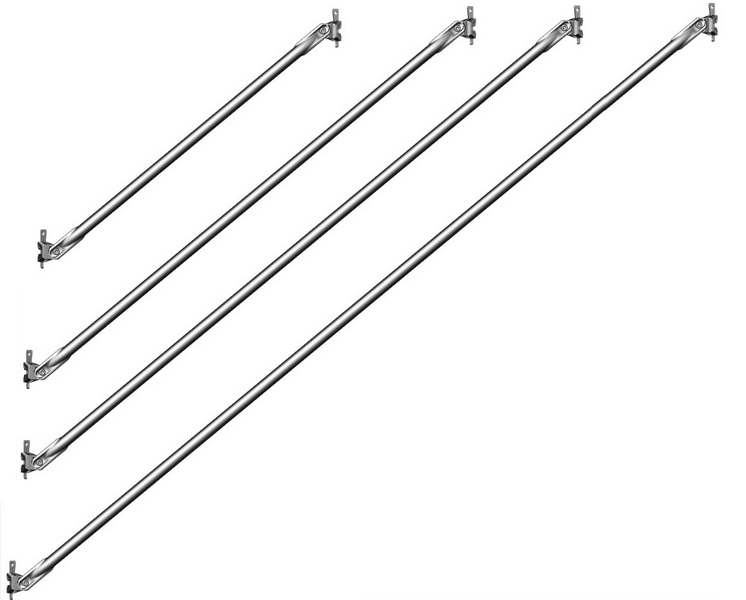

- Braces: These provide additional stability to the scaffold. They are usually made from 48.3mm diameter pipes with a thickness of 2.5mm.

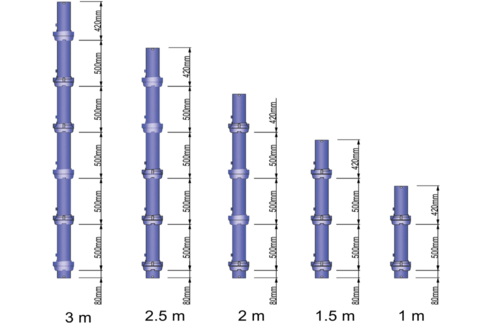

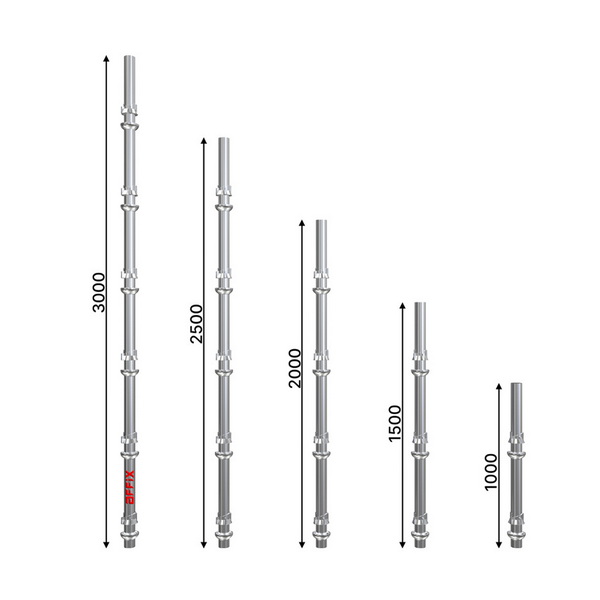

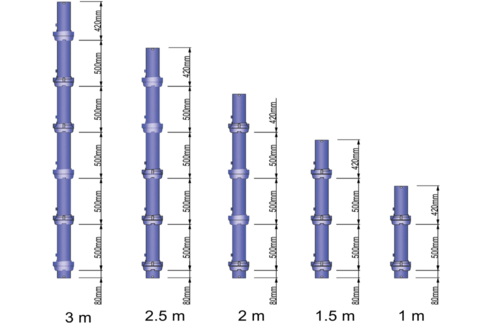

- Cups: The unique feature of cuplock scaffolding, these cups are welded to the standards at 500mm intervals and allow for easy connection of ledgers and braces.

Cuplock Scaffolding Specifications

The specifications of cuplock scaffolding are crucial for ensuring safety and efficiency in construction projects.

Material Specifications

- Material Thickness: Typically 3.2mm for standards and ledgers, with options for 4.0mm thickness.

- Steel Grade: Commonly S355, with S235 also available.

- Surface Treatment: Hot dip galvanized for durability, with options for painted or powder-coated finishes.

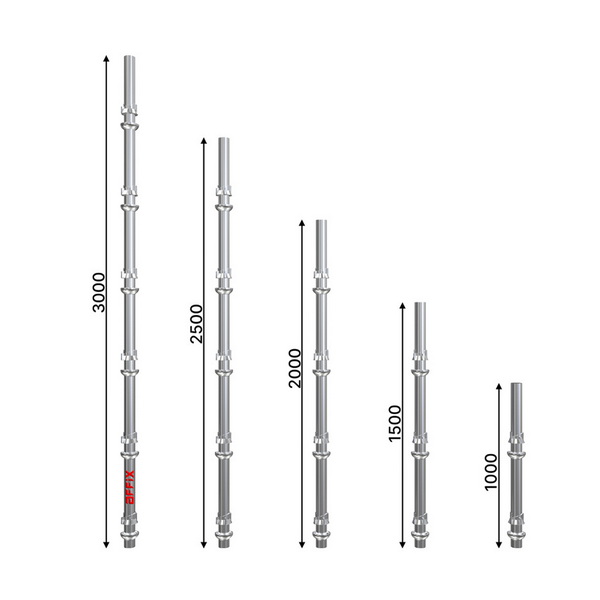

Dimensional Specifications

- Diameter: Standards and ledgers have an outer diameter of 48.3mm.

- Standard Lengths: Available in various lengths, typically from 500mm to 3000mm.

Load Capacity

- Ultimate Load: Varies based on the component and configuration. For example, a 0.5m ledger can support an ultimate load of 48KN.

Assembly and Safety

The assembly process involves placing base plates, erecting standards, fixing ledgers, and ensuring levelness and squareness. Safety features include the use of anchor tubes and eye bolts to secure the scaffold to buildings for heights over 40 meters.

Applications of Cuplock Scaffolding

Cuplock scaffolding is versatile and can be used in various applications:

- Facade Scaffolding: Ideal for exterior work on buildings.

- Formwork Support: Used to support concrete forms during construction.

- Birdcages: Internal scaffolding for complex structures.

- Maintenance Access: Provides safe access for maintenance tasks.

- Stair Access: Used to create stair towers for easy access.

- Mobile Scaffolding: Can be easily moved for different tasks.

Safety Considerations

Safety is paramount when using cuplock scaffolding. Ensure that all components are securely locked, and the structure is regularly inspected for damage or wear. For heights exceeding 40 meters, professional design and safety calculations are necessary.

Assembly Process

The assembly of cuplock scaffolding is straightforward:

1. Base Assembly: Place base plates and attach standards.

2. Erect Standards: Ensure they are level and securely connected.

3. Fix Ledgers: Connect ledgers between standards using cups.

4. Add Braces: Provide additional stability with diagonal braces.

5. Finalize Structure: Ensure all components are securely locked and the structure is level.

Detailed Assembly Steps

For a more detailed assembly process, consider the following steps:

1. Preparation: Ensure the site is clear and level. Lay out base plates according to the scaffold design.

2. Erecting Standards: Place the first standard on each base plate and secure it. Use a spirit level to ensure it is perfectly vertical.

3. Fixing Ledgers: Connect ledgers between standards using the cups. Ensure ledgers are level and securely locked.

4. Adding Braces: Install diagonal braces to provide additional stability to the scaffold.

5. Final Inspection: Conduct a thorough inspection to ensure all components are securely locked and the structure is level.

Advanced Applications

Cuplock scaffolding can also be used in more complex scenarios:

- Bridge Scaffolding: Used for bridge maintenance and repair.

- Shipyard Scaffolding: Ideal for shipbuilding and repair projects.

- High-Rise Construction: Used for exterior work on high-rise buildings.

Customization Options

Cuplock scaffolding can be customized to fit specific project needs:

- Specialized Components: Custom-made components can be designed for unique applications.

- Special Coatings: Additional coatings can be applied for enhanced durability in harsh environments.

Environmental Considerations

When using cuplock scaffolding, consider the environmental impact:

- Material Recycling: Ensure that scaffolding materials are recycled when possible.

- Noise Reduction: Use noise-reducing measures during assembly to minimize disturbance.

Training and Certification

Proper training is essential for safe and efficient use of cuplock scaffolding:

- Operator Training: Ensure that all operators are trained in assembly, use, and dismantling procedures.

- Regular Inspections: Conduct regular inspections to ensure compliance with safety standards.

Conclusion

Cuplock scaffolding is a reliable and efficient system for construction projects. Its modular design and ease of assembly make it a preferred choice for various applications. Understanding the standard specifications and safety considerations is crucial for ensuring safe and effective use.

FAQ

1. What are the main components of cuplock scaffolding?

The main components include standards, ledgers, braces, and cups. Standards are the vertical tubes, ledgers are the horizontal tubes, braces provide stability, and cups are the locking mechanism.

2. What is the typical material used for cuplock scaffolding?

Cuplock scaffolding is typically made from S355 steel grade with a thickness of 3.2mm. The surface treatment is often hot dip galvanized for durability.

3. How is cuplock scaffolding assembled?

Assembly involves placing base plates, erecting standards, fixing ledgers, and adding braces. The structure must be level and securely locked at all times.

4. What are the common applications of cuplock scaffolding?

Cuplock scaffolding is used for facade scaffolding, formwork support, birdcages, maintenance access, stair access, and mobile scaffolding.

5. What safety considerations should be taken into account?

Ensure all components are securely locked, regularly inspect for damage, and use anchor tubes and eye bolts for heights over 40 meters. Professional design is required for high structures.

Citations:

[1] https://www.wm-scaffold.com/cup-lock-scaffold.html

[2] https://www.youtube.com/watch?v=wBKilb9ALEY

[3] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/

[4] https://www.alibaba.com/showroom/cuplock-scaffolding-design.html

[5] https://www.sparsteel.com/blog/cuplock-scaffolding-types-uses-and-benefits/

[6] https://www.thehansindia.com/life-style/sparsteel-cuplock-scaffolding-the-leading-scaffolding-system-in-the-middle-east-910041

[7] https://www.internationalscaffolding.com/projects/what-is-a-cuplock-scaffolding-system/

[8] https://www.labour.gov.hk/eng/public/os/B/mss.pdf

[9] https://www.wm-scaffold.com/cuplock-scaffolding-standard.html

[10] https://www.linkedin.com/pulse/cuplock-system-scaffolding-versatile-quality-assured-scaffold-mishra