Content Menu

● What Is H Frame Scaffolding?

● H Frame Scaffolding Details: Key Components

● H Frame Scaffolding Specifications

● How to Assemble H Frame Scaffolding

>> Step-by-Step Assembly Process

● H Frame Scaffolding Details: Features and Advantages

● Applications of H Frame Scaffolding in Construction

● H Frame Scaffolding Details: Technical and Safety Standards

>> Technical Specifications

>> Safety Standards

● Best Practices and Common Mistakes

>> Best Practices

>> Common Mistakes to Avoid

● H Frame Scaffolding in Action: Case Studies

>> Case Study 1: High-Rise Residential Construction

>> Case Study 2: Bridge Repair Project

>> Case Study 3: Industrial Plant Maintenance

● Advanced Techniques for Specialized Projects

>> Sloped or Uneven Terrain

>> Curved Structures

>> Integration with Other Systems

● H Frame Scaffolding Details: Maintenance and Longevity

● Innovations in H Frame Scaffolding

>> Smart Scaffolding

>> Lightweight Materials

>> Eco-Friendly Designs

● Conclusion

● FAQ

>> 1. What is the maximum height for H frame scaffolding in construction?

>> 2. How often should H frame scaffolding be inspected?

>> 3. Can H frame scaffolding be customized for special projects?

>> 4. What are the most common safety mistakes with H frame scaffolding?

>> 5. Is H frame scaffolding suitable for both indoor and outdoor use?

H frame scaffolding is one of the most trusted, versatile, and widely used scaffolding systems in the construction industry. Its robust design, adaptability, and ease of assembly make it indispensable for projects ranging from high-rise buildings to bridge repairs and industrial maintenance. This comprehensive guide explores h frame scaffolding details, including its components, assembly, applications, safety standards, and best practices-supported by real-world examples.

What Is H Frame Scaffolding?

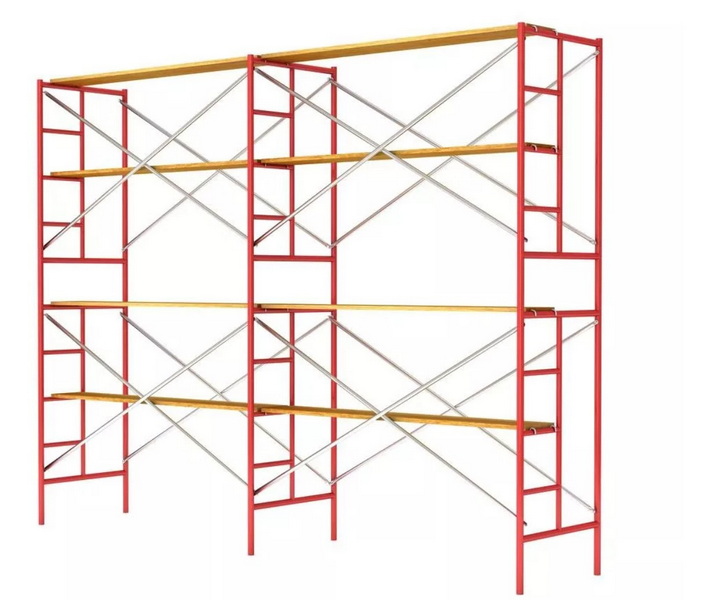

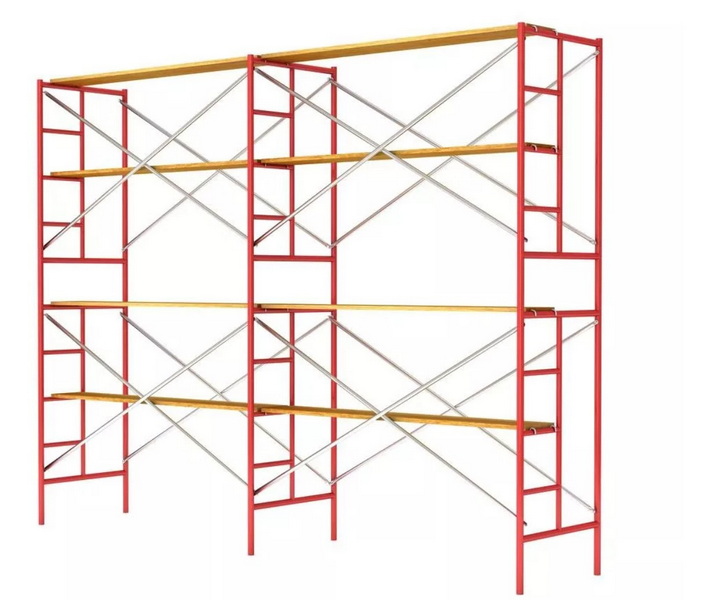

H frame scaffolding is a modular support system consisting of vertical H-shaped frames, cross braces, and horizontal ledgers. The system is named for its distinctive “H” shape, formed by two vertical bars joined by horizontal crossbars. This configuration delivers exceptional stability and load-bearing capacity, making it a preferred choice for construction projects that require safe, elevated work platforms.

H Frame Scaffolding Details: Key Components

Understanding the components is essential to mastering h frame scaffolding details:

- H Frames: The backbone of the system, providing vertical support and stability.

- Cross Braces: Diagonal connectors that lock frames together, preventing sway and movement.

- Horizontal Ledgers: Support beams that distribute weight and form the working platform base.

- Base Plates: Placed under the frames to ensure a stable foundation.

- Platforms (Wood Planks/Metal Decks): Walkways for workers and materials.

- Guardrails & Toe Boards: Safety features to prevent falls and injuries.

- Joint Pins & Couplers: Securely connect scaffold sections for modular expansion.

H Frame Scaffolding Specifications

| Component | Standard Size Range | Material | Function |

| H Frame | 1–2 meters high, 0.76–1.5m wide | Steel/Aluminum | Vertical support |

| Cross Braces | 1.2–2.5 meters length | Steel | Rigidity, prevents sway |

| Ledgers | 1.2–2.5 meters length | Steel | Distribute load, support platforms |

| Platforms | Custom width/length | Wood/Metal | Walkway for workers |

| Base Plates | 100–150mm square | Steel | Stable footing |

| Guardrails/Boards | Custom | Steel/Wood | Fall protection |

How to Assemble H Frame Scaffolding

Step-by-Step Assembly Process

1. Site Preparation: Ensure the ground is level and stable. Place base plates for support.

2. Install H Frames: Position vertical frames upright at the required spacing.

3. Connect Cross Braces: Attach diagonal braces to lock frames together, forming rigid bays.

4. Add Ledgers: Secure horizontal ledgers between frames for platform support.

5. Lay Platforms: Place planks or metal decks across ledgers to create a safe walkway.

6. Install Guardrails & Toe Boards: Attach safety rails and boards on all open sides.

7. Stack for Height: For multi-level access, stack additional frames and repeat the process.

8. Inspection: Check all connections, ensure stability, and verify compliance with safety standards.

H Frame Scaffolding Details: Features and Advantages

- Superior Stability: The “H” configuration and cross bracing provide exceptional rigidity.

- High Load Capacity: Supports heavy workers, tools, and materials-up to 300kg/m² or more.

- Quick Assembly/Disassembly: Prefabricated components lock together without special tools.

- Modular Design: Easily adapts to various heights and layouts.

- Durability: Made from galvanized steel or aluminum for corrosion resistance and long service life.

- Safety: Integrated guardrails, toe boards, and non-slip platforms meet international safety standards.

Applications of H Frame Scaffolding in Construction

H frame scaffolding's versatility makes it suitable for a wide range of construction and industrial projects:

- High-Rise Building Construction: Provides safe access for workers at multiple elevations, supports façade work, window installation, and plastering.

- Bridge Construction & Repairs: Enables access to difficult-to-reach sections, supports heavy loads during maintenance.

- Industrial Facilities: Used for equipment installation, maintenance, and repairs in refineries, factories, and power plants.

- Exterior Renovations: Ideal for painting, cladding, insulation, and window replacement on tall structures.

- Infrastructure Projects: Supports work on tunnels, viaducts, hydroelectric plants, and subway stations.

- Event Staging: Temporary platforms for events, signage, and lighting installations.

H Frame Scaffolding Details: Technical and Safety Standards

Technical Specifications

- Frame Heights: Typically 1–2 meters per unit; stackable to 12 meters or more.

- Width Between Frames: Commonly 0.76–1.5 meters.

- Load Capacity: Up to 6kN per leg, depending on configuration and manufacturer.

- Material: High-grade steel (S235/S355), aluminum for lighter applications.

- Corrosion Resistance: Painted, powder-coated, or hot-dip galvanized finishes.

Safety Standards

- Compliance: Meets EN 12810/12811, OSHA, ANSI, and other international standards.

- Guardrails & Toe Boards: Required on all open sides above 2 meters.

- Base Stability: Use of base plates and adjustable jacks for uneven ground.

- Regular Inspections: Mandatory checks before each use and after adverse events.

- Worker Training: Personnel must be trained in assembly, use, and emergency procedures.

Best Practices and Common Mistakes

Best Practices

- Always follow manufacturer guidelines for assembly and use.

- Conduct daily inspections for wear, damage, or loose connections.

- Train all workers in scaffold safety and fall protection.

- Use personal protective equipment (PPE): helmets, harnesses, non-slip footwear.

- Monitor load distribution-never exceed rated capacity.

Common Mistakes to Avoid

- Incomplete or improper assembly

- Ignoring weight limits and overloading

- Skipping regular inspections

- Neglecting fall protection measures

- Placing scaffolding on unstable or uneven ground

H Frame Scaffolding in Action: Case Studies

Case Study 1: High-Rise Residential Construction

A 20-story residential tower in Mumbai used H frame scaffolding for façade cladding and painting. The modular system allowed for rapid assembly and adjustment as the building rose, enabling safe, efficient work at every level.

Case Study 2: Bridge Repair Project

During a major bridge renovation, engineers chose H frame scaffolding for its high load capacity and ability to adapt to uneven surfaces. The system's stability and ease of movement between sections reduced downtime and improved worker safety.

Case Study 3: Industrial Plant Maintenance

A refinery shutdown required quick access to multiple equipment levels. H frame scaffolding was deployed for its fast setup and reconfiguration, minimizing operational delays and ensuring compliance with strict safety protocols.

Advanced Techniques for Specialized Projects

Sloped or Uneven Terrain

H frame scaffolding can be adapted for challenging terrains using adjustable base plates and screw jacks. For example, in bridge construction over water or hilly areas, these adjustments ensure a level platform despite uneven ground.

Curved Structures

While H frame scaffolding is inherently linear, it can be combined with flexible components like swivel couplers or tube-and-clamp systems to accommodate curved architectural designs, such as domes or arched facades.

Integration with Other Systems

For hybrid projects, H frame scaffolding can be paired with suspended platforms or cantilevered sections to access overhangs or areas with limited ground space.

H Frame Scaffolding Details: Maintenance and Longevity

- Regular Cleaning: Remove debris and dirt after each use.

- Corrosion Protection: Inspect for rust, repaint or galvanize as needed.

- Component Replacement: Replace bent, cracked, or worn parts immediately.

- Storage: Store frames and braces in dry, secure areas to prolong lifespan.

Innovations in H Frame Scaffolding

Smart Scaffolding

IoT-enabled sensors are now being integrated into H frame scaffolding to monitor load distribution, environmental conditions, and structural integrity in real time. This technology alerts workers to potential issues, such as overloading or instability, before they become hazards.

Lightweight Materials

Advanced aluminum alloys and composite materials are reducing the weight of H frames without compromising strength, making transport and assembly faster and safer.

Eco-Friendly Designs

Manufacturers are adopting sustainable practices, such as using recycled steel and non-toxic coatings, to minimize the environmental impact of scaffolding production and disposal.

Conclusion

H frame scaffolding is a cornerstone of modern construction, offering unmatched stability, adaptability, and safety for a variety of projects. Its modular design, high load capacity, and compliance with international standards make it a go-to solution for contractors worldwide. By understanding h frame scaffolding details, following best practices, and prioritizing safety, construction teams can maximize productivity and minimize risks on any job site. As technology advances, innovations like smart monitoring and eco-friendly materials will further enhance its role in sustainable and efficient construction.

FAQ

1. What is the maximum height for H frame scaffolding in construction?

H frame scaffolding can typically be stacked safely to heights exceeding 12 meters (about 40 feet), provided that stability, load limits, and safety regulations are strictly followed.

2. How often should H frame scaffolding be inspected?

Scaffolding should be inspected before each use, after severe weather, and at regular intervals during extended projects. Any damaged or worn components must be replaced immediately.

3. Can H frame scaffolding be customized for special projects?

Yes, H frame scaffolding systems can be tailored in height, width, and platform configuration to suit unique construction requirements. Custom accessories like stairs, ladders, and adjustable jacks are also available.

4. What are the most common safety mistakes with H frame scaffolding?

Typical mistakes include improper assembly, overloading, neglecting inspections, and failing to use fall protection. Training and adherence to guidelines are essential to avoid these hazards.

5. Is H frame scaffolding suitable for both indoor and outdoor use?

Absolutely. H frame scaffolding's modular design and corrosion-resistant materials make it ideal for both interior and exterior construction, maintenance, and renovation projects.