Introduction

Frame scaffolding, also known as H-frame scaffolding or tubular welded scaffolding, is a popular choice in construction for providing sturdy and reliable support structures. In this guide, we'll dive into the components, types, benefits, and safety requirements of frame scaffolding, helping you make informed decisions for your projects.

|Nanjing TP Scaffold provides high-quality frame scaffolding and accessories. Visit our frame scaffolding page for detailed product specifications and competitive pricing.

What is Frame Scaffolding?

Frame scaffolding, also known as tubular welded scaffolding, is a type of scaffold built from prefabricated frames used as temporary support in various construction projects.

Components of Frame Scaffolding

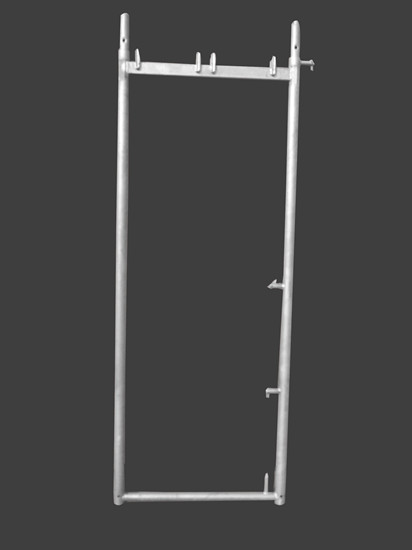

Scaffolding Frames

Scaffolding frames are steel structures made up of two horizontal and two vertical tubes welded together. This design replaces the need for connecting standards and ledgers with fittings, enhancing efficiency and saving labor. The frames resemble an "H," hence the name H Frame Scaffolding.

Cross Braces

Cross braces are typically made of two galvanized pipes connected to form an "X" shape. They attach to the locking pins on the frame to provide support and stability. The length of the cross brace is determined by the locking distance and scaffold board / platform length, with common sizes being 7’x 4’ and 10’x 4’.

Scaffold Base Jacks

Scaffold base jacks consist of a base plate and a threaded rod or tube welded together, with a nut for height adjustment. The outer diameter of the base jack should match the inner diameter of the frame leg, allowing it to be inserted for load distribution and ground leveling.

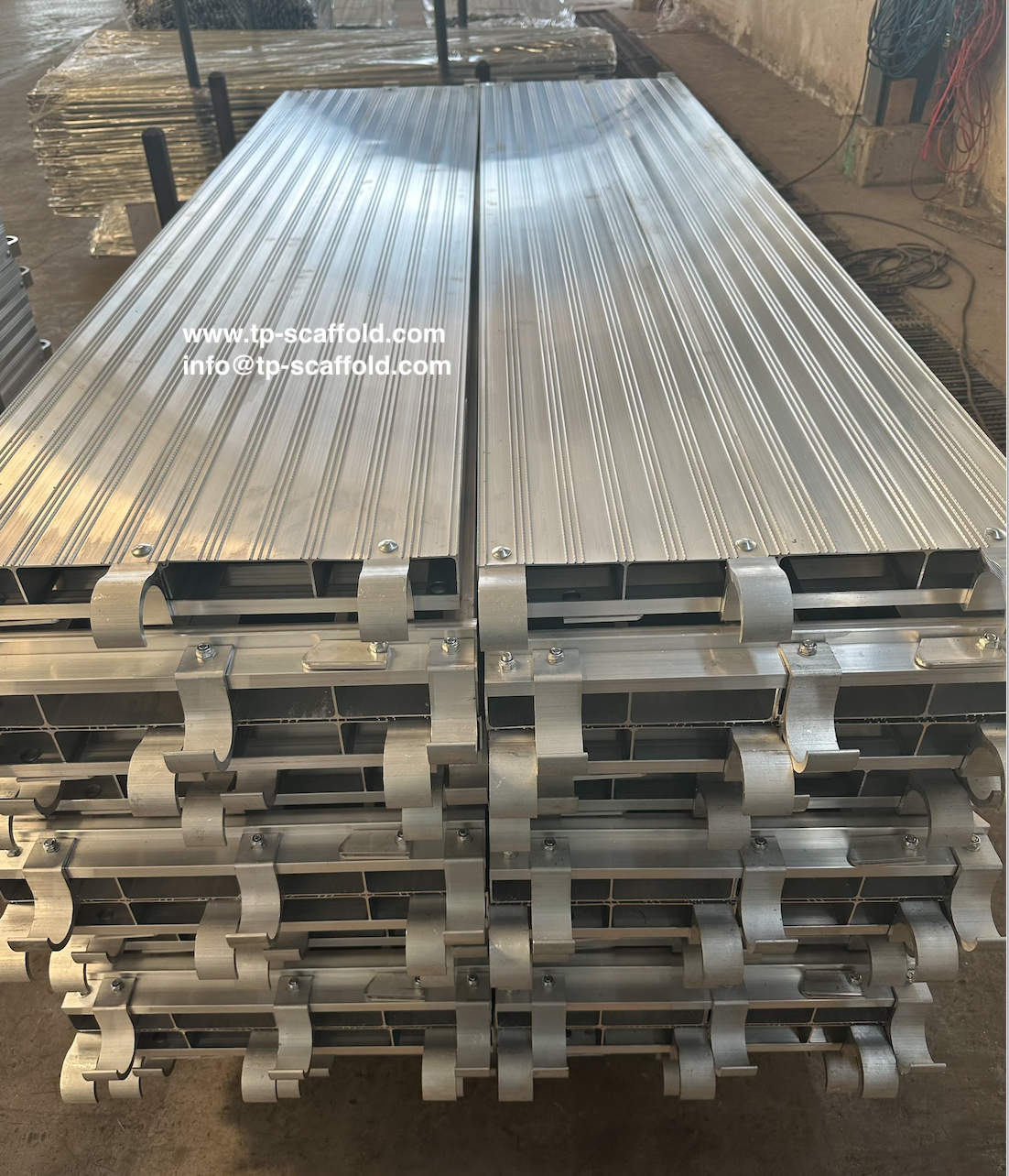

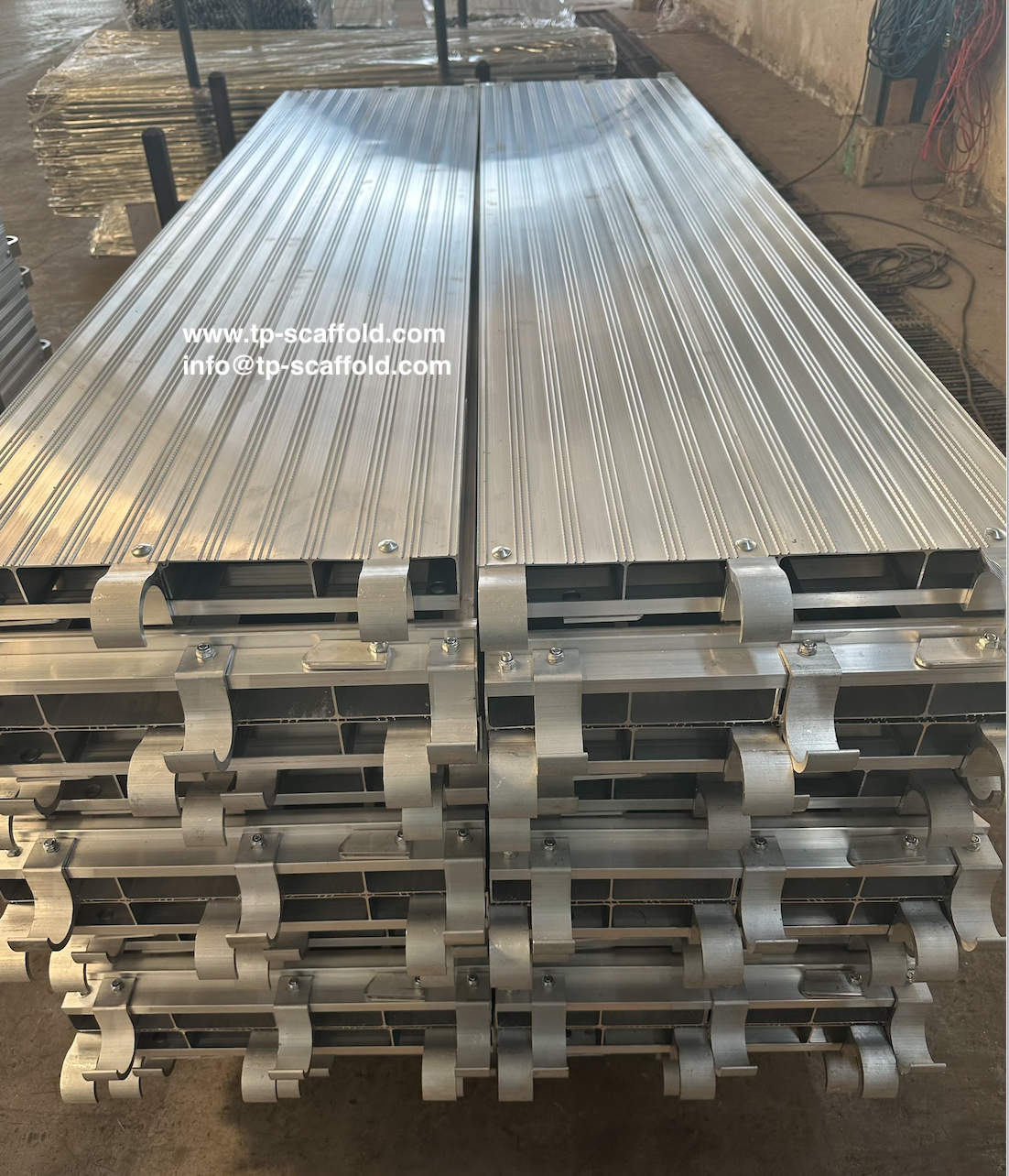

Scaffold Boards

Scaffold boards are platforms placed on the top horizontal bars of the frames for material storage and worker access. They can be made from metal, aluminum, or wood.

Coupling Pins

Coupling pins are connecting pins with a collar riveted on the outside, fitted onto the frame legs to stack multiple scaffolding frames for different heights.

Guard Rails

Guard rails are single galvanized pipes used when scaffolding height exceeds 42". Common sizes include 5’, 7’, and 10’.

There are various types of frame scaffolding components to realise different fuctions in the construction work. The above are some basic elements for your review. Click here to learn more components for frame scaffolding.

Types of Scaffolding Frames

Scaffolding frames come in various types, with the most common being:

By Material

Steel Frame

Most frames are made of steel, offering the best choice in terms of functionality and cost.

Aluminum Frames

Often used as shoring frames in formwork due to their high load capacity and ease of transport and assembly. Aluminum frames are also used in mobile scaffolding for small indoor and outdoor jobs.

By Shape and Function

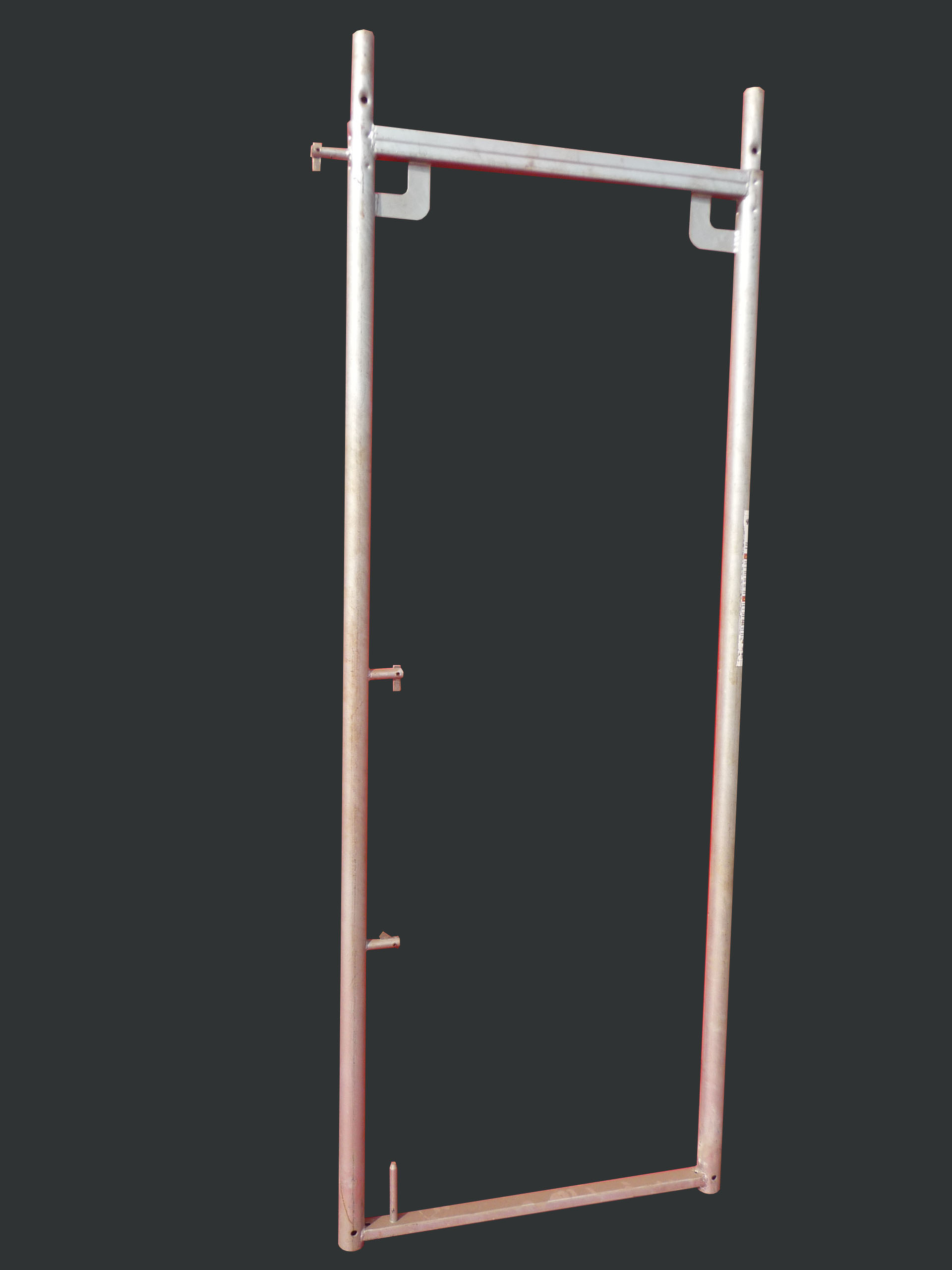

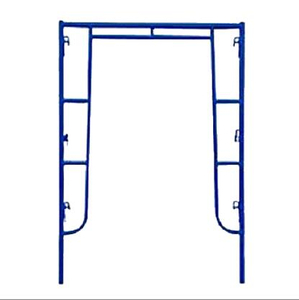

Mason Frame Scaffolding

Also called ladder or step frames, with rungs on one or both sides for ladder functionality. Frames with rungs on both sides are called box frames.

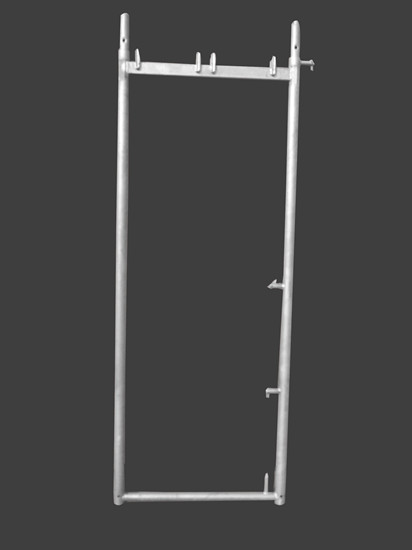

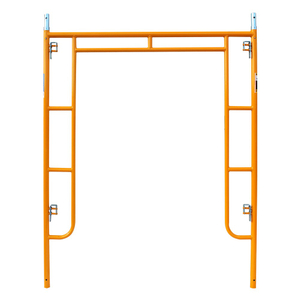

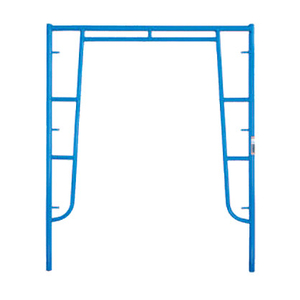

Walk Through Frame Scaffolding

Also known as arch frames, these are open at the bottom for easy passage and allow workers to traverse and work on multiple levels.

Folding A Frame Scaffolding

Also known as trestle frame scaffolding, it is foldable and used for single-story residential or wall masonry work, providing elevated access. Common sizes are 4’ and 6’.

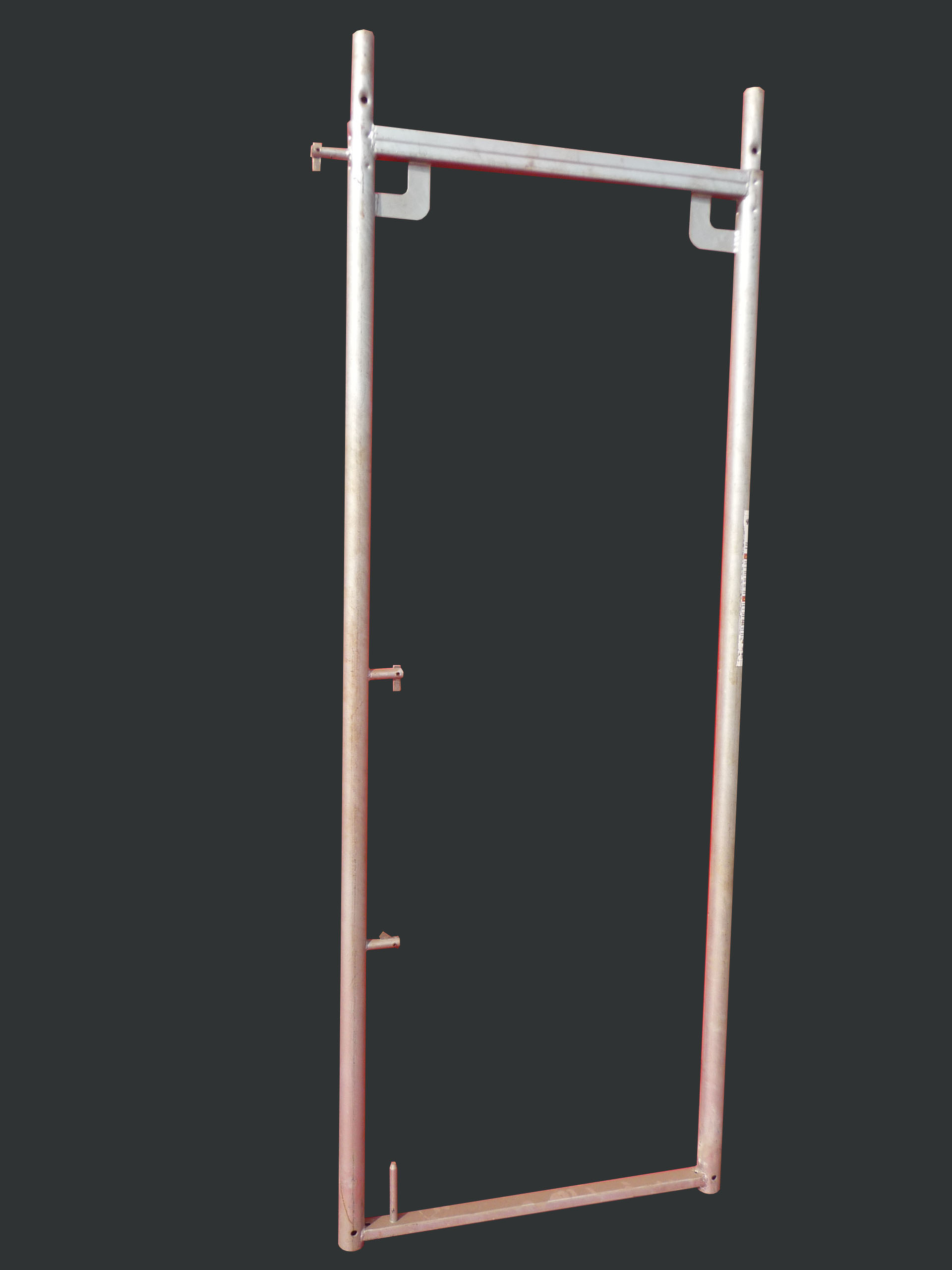

Shoring Frame Scaffolding

A type of heavy-duty frame primarily used for support, different from other frames, and mainly for supporting concrete floors, ceilings, and excavation.

Layher Frame Scaffolding

Developed by Layher, commonly used in Europe with U transoms and U-shaped platforms.

Plettac Frame Scaffolding

Another common European frame used in façade scaffolding, similar in appearance to the Layher frame but with different locking pins, using star pins on top.

Italian Frame Scaffolding

Similar to walk-through frames but usually with diagonal braces welded to the top horizontal and vertical tubes, commonly used in Italy and surrounding countries.

In Australia and Brazil, scaffolding frames are used with minor differences in shape and size.

| Visit www.tp-scaffold.com for a full selection of scaffolding frames and accessories.

Surface Treatments for Frame Scaffolding

Hot-Dip Galvanizing

The best surface treatment for protecting frames, allowing for maximum usage and adaptability to various climates. However, due to its high cost, it is only used in projects with high environmental demands.

Powder Coating

The most common surface treatment, more eco-friendly and with stronger adhesion than painting. It is less expensive than galvanizing and available in various bright colors like red, yellow, and blue, unlike the silver of galvanized frames.

Pre-Galvanizing

Some customers, especially from Southeast Asia, choose pre-galvanized frames, made from pre-galvanized pipes welded and then painted. Although cheaper than hot-dip galvanized frames, we do not recommend them due to potential rusting at weld points and health risks during welding.

Application of Frame Scaffolding

Construction

Frame scaffolding is used in residential, commercial, and industrial construction for tasks such as painting, roofing, window installation, masonry, plastering, and façade maintenance.

Film Production and Event Planning

In these industries, scaffolding frames are used to create temporary structures like stages, lighting setups, and other required structures.

Advantages of Frame Scaffolding

Flexibility: Suitable for various construction activities with a wide range of sizes and shapes, allowing for different heights.

Ease of Use: Prefabricated frames with pre-welded tubes reduce assembly and disassembly time, lower labor costs, and increase worker efficiency.

Durability: Made from high-strength steel (such as Q355) or aluminum, providing strong load-bearing capacity. Hot-dip galvanizing and powder coating prevent corrosion, adapting to various climates.

Visibility: Bright colors enhance safety by making scaffolding noticeable from a distance.

Disadvantages of Frame Scaffolding

Scaffolding frames have no major downsides. However, they occupy significant space during production and transport, increasing shipping costs, especially for small orders.

Safety Requirements for Frame Scaffolding

The scaffolding and its components must support four times their rated load.

Use cross braces to keep scaffolding stable and secure.

Employ outriggers when stacking scaffolding frames.

Use base plates or base jacks.

Use guardrails or personal fall arrest systems above 10 feet to protect workers.

Train employees on scaffold assembly and disassembly before work.

Ensure all locking pins are in place before use.

OSHA requires scaffold platforms to be fully planked or decked with proper guardrails, mid-rails, and toe boards.

| Read our scaffolding safety checklist for more tips on maintaining a safe work environment.

FAQ

What are the most popular scaffolding frame sizes?

Mason Frame Scaffolding: 5’x 5’

Walk Through Frame Scaffolding: 5’x 6’4”

Folding A Frame Scaffolding: 4’, 6’

Snap-On Scaffolding Frame: 3’x 6’8”

Shoring Frame Scaffolding: 6’x 4’

Plettac Frame: SL 70/100

Italian Frame Scaffolding: 2m x 1.05m

What are the most popular scaffolding frames in the USA?

Safway Frame: Usually blue with drop locks.

Waco Frame: Usually red with fast locks or candy cane locks.

Vanguard Frame: Usually blue with Vanguard locks.

Metaltech Frame: Usually blue with Canadian locks.

Bil-jax Frame: Usually yellow with C locks.

These are the most famous scaffolding brands in North America, with varying usage habits by region.

Conclusion

This overview of frame scaffolding covers its types, surface treatments, advantages, disadvantages, and applications. Understanding these aspects is crucial for selecting the right scaffolding and adhering to safety rules. Nanjing Tuopeng Scaffold is dedicated to producing and selling various types of scaffolding components. With extensive experience and professionally trained welders, we ensure that your frames are prepared to your specifications, with attention to detail in surface treatments like hot-dip galvanizing and powder coating. Our efficient packing maximizes container use, saving on shipping costs, especially when freight rates are high. We also offer labeling services for customized product labels.

Contact us for the latest prices.