Fixed Scaffolding Coupler Decorations:

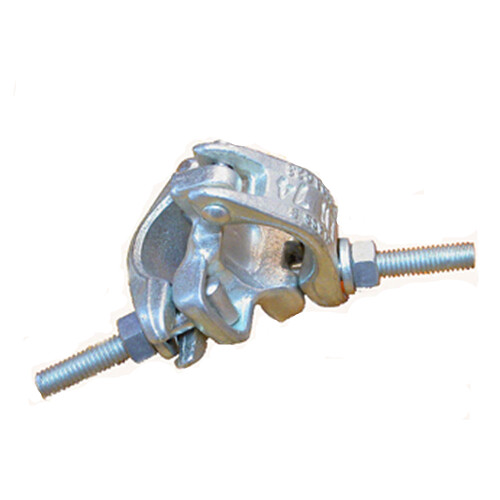

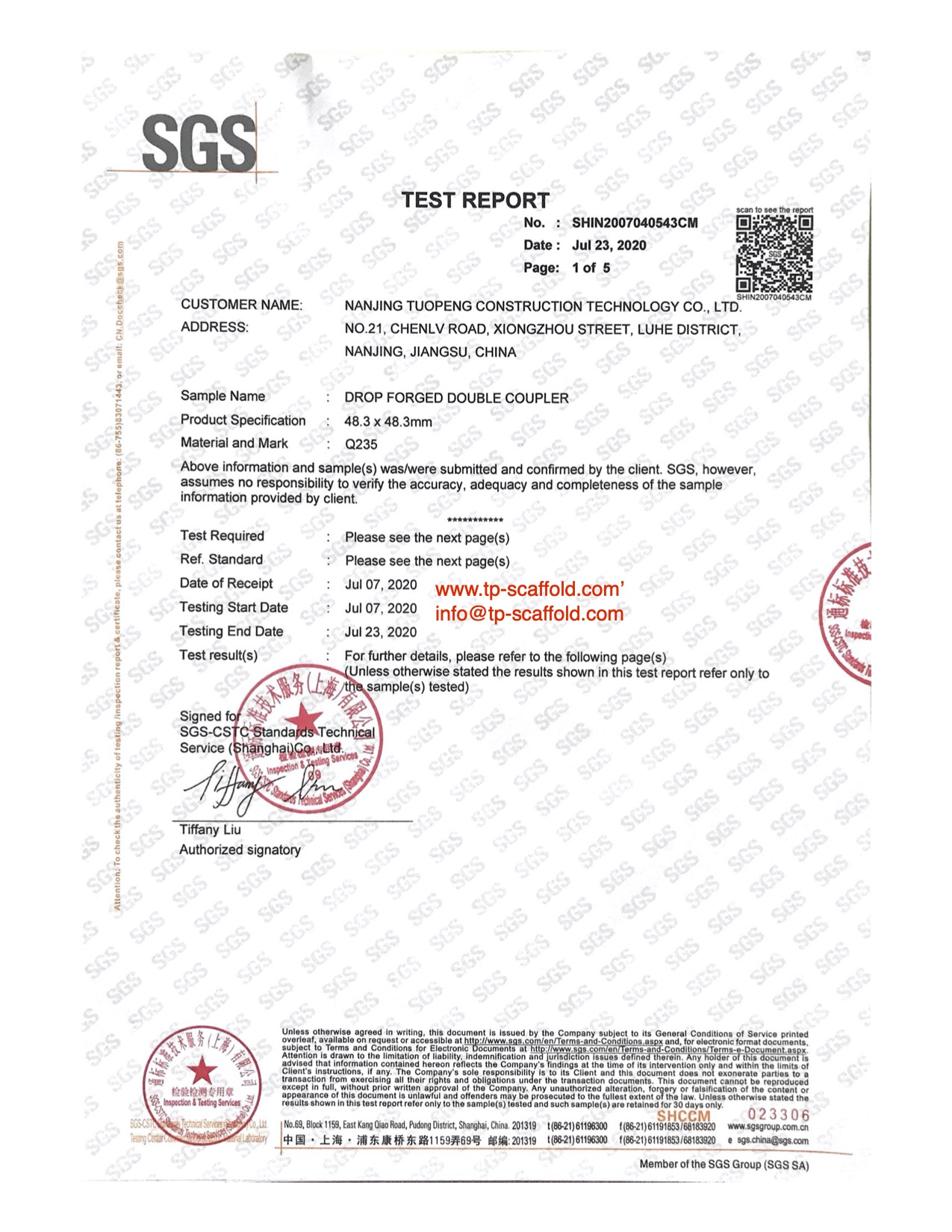

1. Drop forged fixed scaffolding coupler building British style, which is widely used in global market to connect 48.3mm tubes at 90 degrees.

2. Unit weight: 0.97 kg

3. Surface finish: electro galvanized, or hot dip galvanized

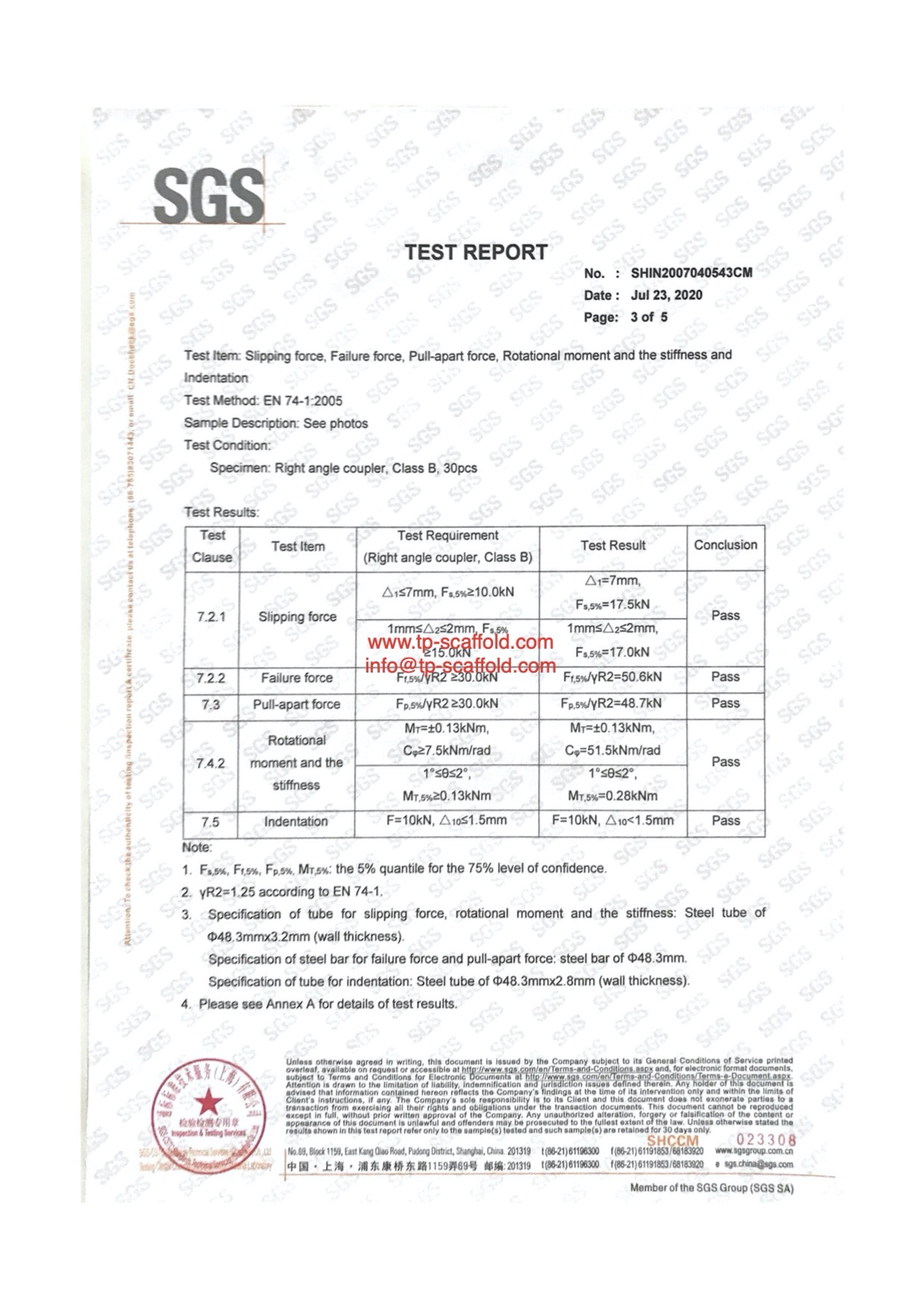

4. Meeting EN74 and BS1139 Standard

5. Packing: 25pcs in one bag, 50 bags are packed on one wood or steel pallet

6. Rich experience in producing all types of couplers, pressed type and drop forged type. We have our own forging line

7. Fast delivery

Drop Forged Double Coupler – Steel Scaffolding Clamp

A fixed ninety degree, rigid coupling is used for connecting two 48.3mm tubes at right angles. This heavy duty fitting is intended for use in the construction of all types of scaffolding, as well as lighting rigs, staging, and guard rails.

All of our drop forged scaffold fittings are zinc plated for longer life and manufactured in accordance with BS1139 & EN74 and tested to ensure the highest level of quality control. Our drop forged doubles are Class B.

This fitting is also available as a pressed steel fitting.

We are a honest supplier, manufacturer, exporter, trader of a wide range of scaffolding couplers in China. If you did not find the right coupler from the following list, please contact us.

| No. | Item | Weight (kg) |

| 1 | Drop forged fixed coupler British type:48.3x48.3 | 0.97 |

| 2 | Drop forged swivel coupler British type:48.3x48.3 | 1.15 |

| 3 | Drop forged putlog coupler | 0.65 |

| 4 | Pressed sleeve,end to end connector | 1.02 |

| 5 | Drop forged fixed girder coupler | 1.5 |

| 6 | Drop forged swivel girder coupler | 1.6 |

| 7 | Ladder coupler | 0.72 |

| 8 | Drop forged inner joint pin | 1.1 |

| 9 | Board retaining coupler | 0.63 |

| 10 | Pressed right angle coupler British type | 0.85 |

| 11 | Pressed swivel coupler British type | 1.02 |

| 12 | Pressed putlog coupler | 0.63 |

| 13 | Pressed inner joint pin | 0.68 |

| 14 | Drop forged fixed coupler American type:48.3x48.3 | 1.65 |

| 15 | Drop forged swivel coupler American type:48.3x48.3 | 1.75 |

| 16 | Drop forged half coupler British type | 0.65 |

| 17 | Drop forged half coupler American type | 0.92 |

| 18 | Drop forged fixed coupler German type:48.3x48.3 | 1.05 |

| 19 | Drop forged swivel coupler German type:48.3x48.3 | 1.25 |

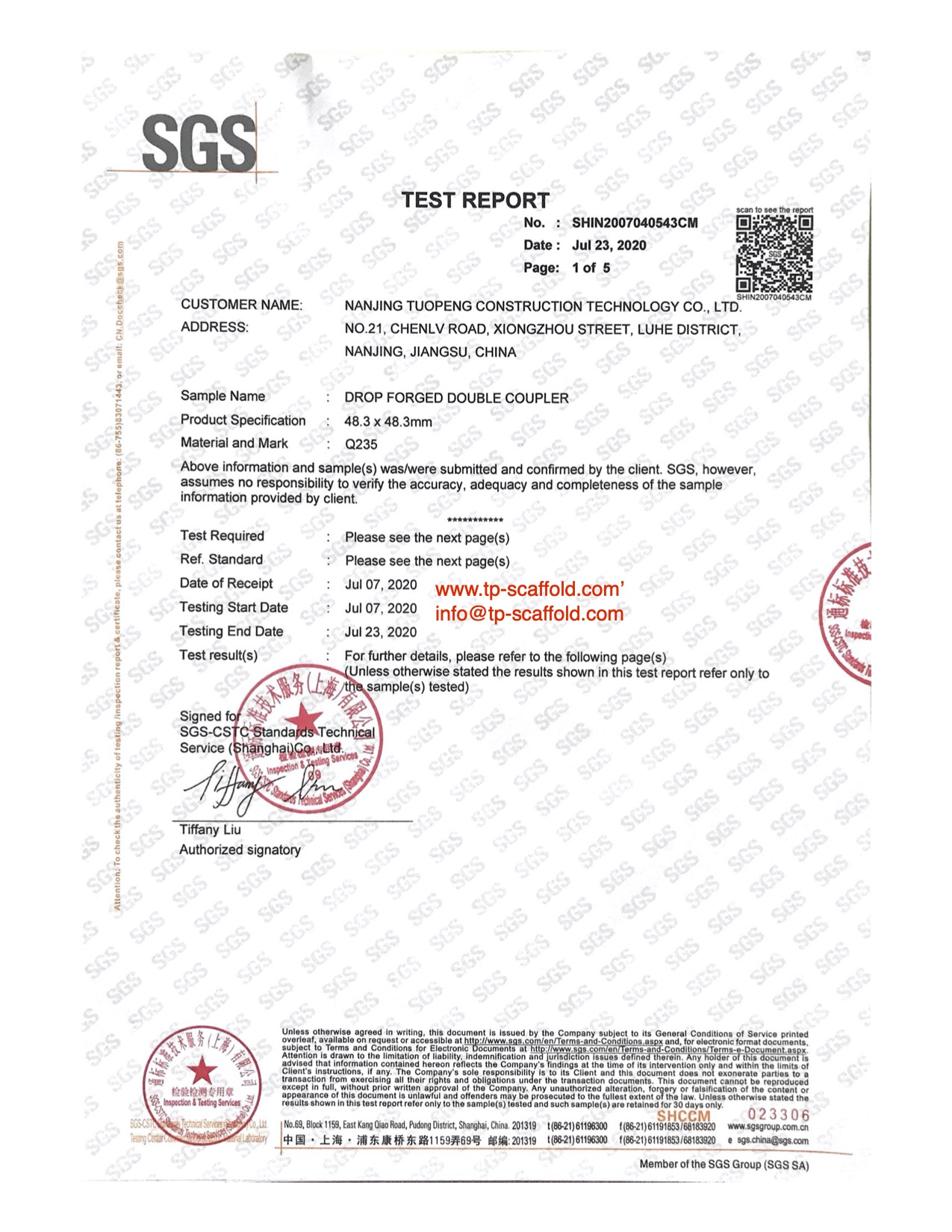

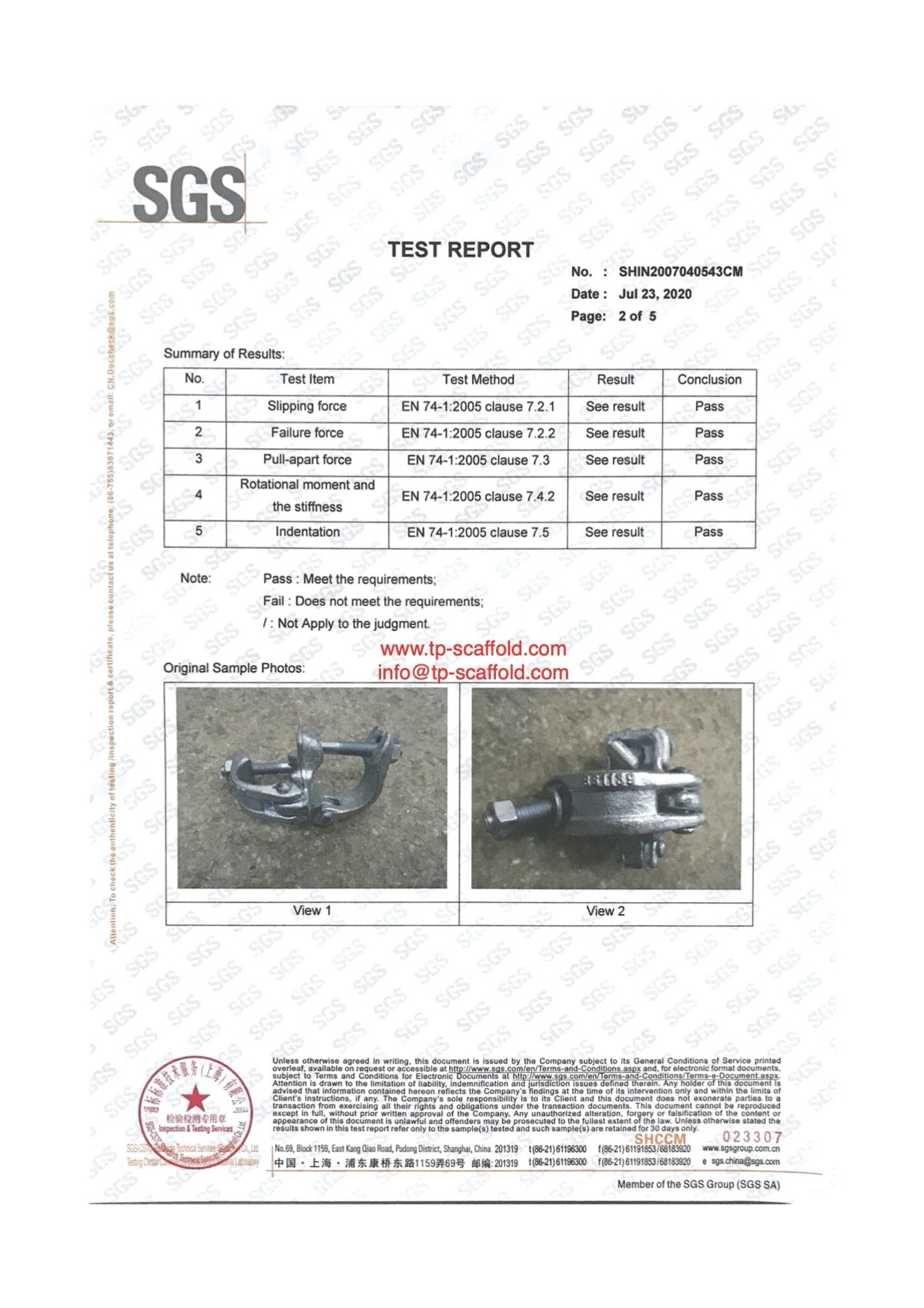

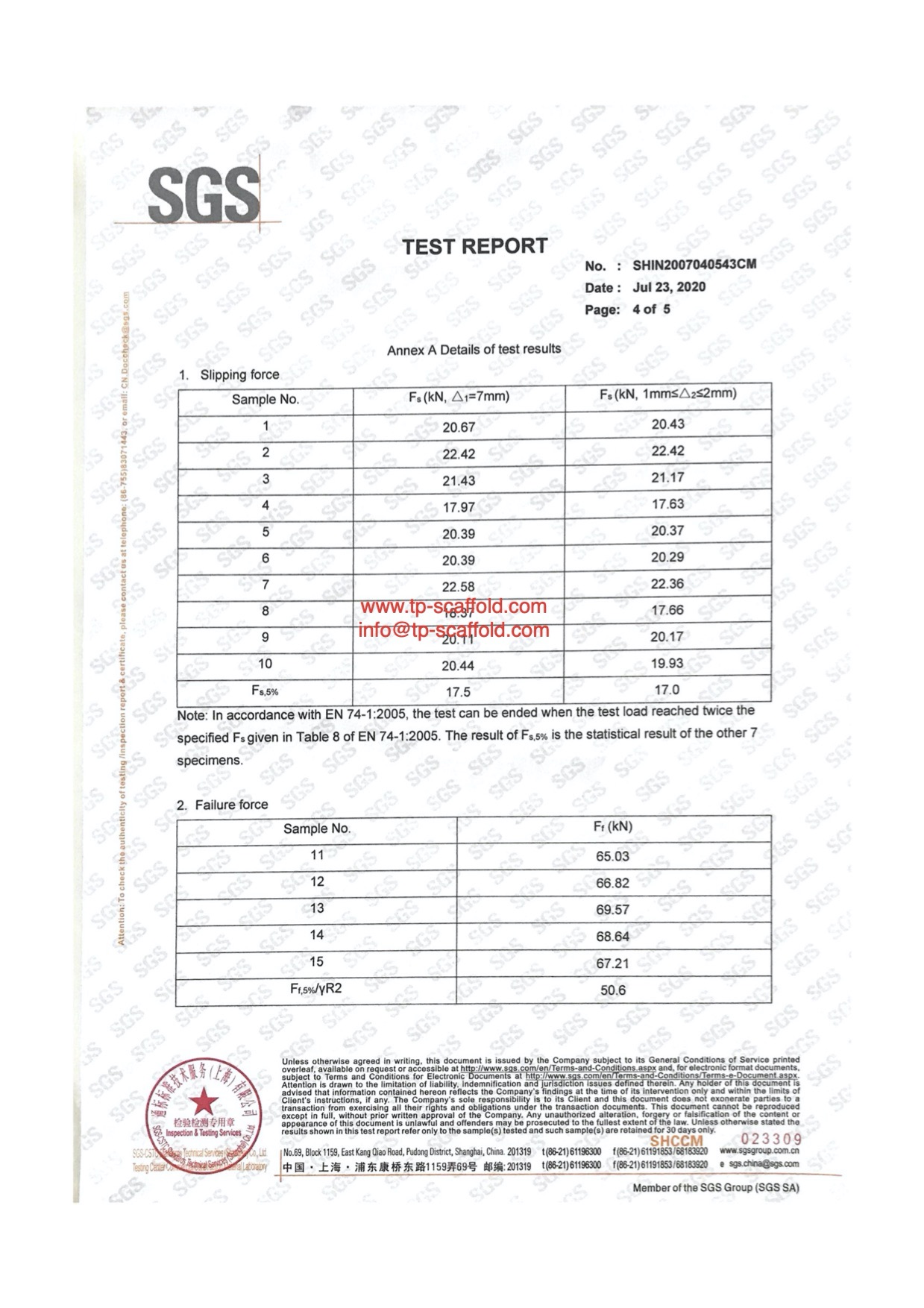

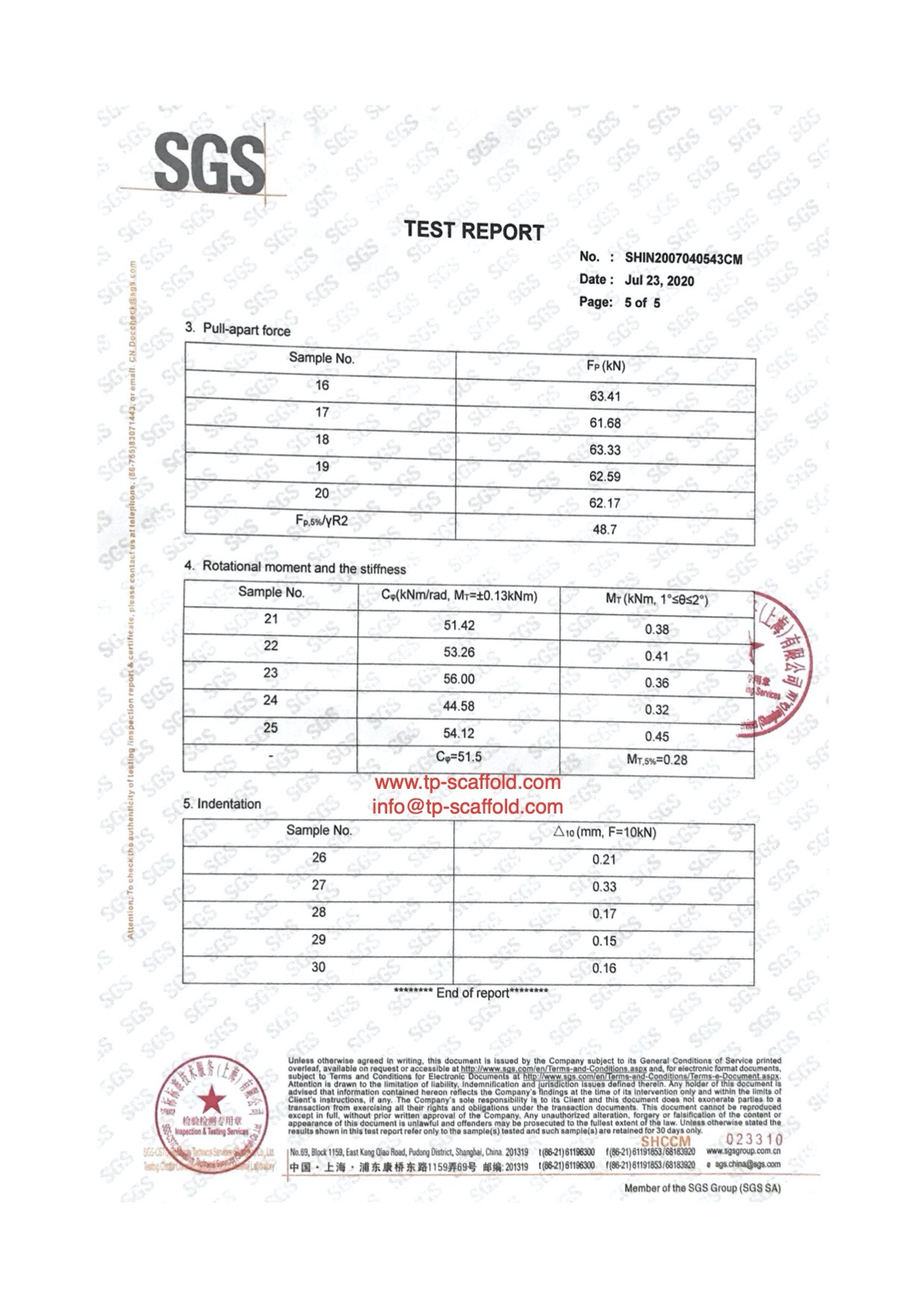

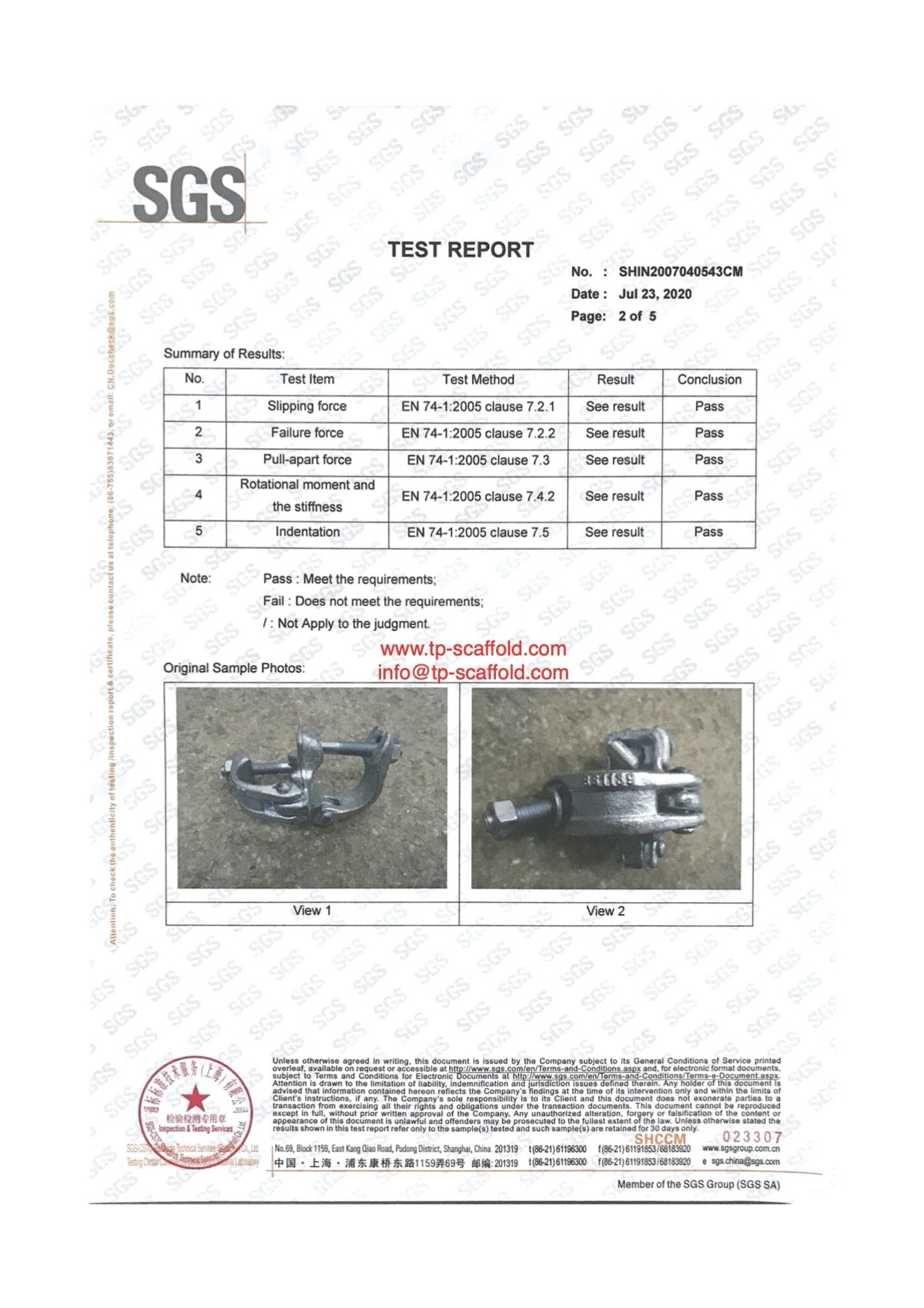

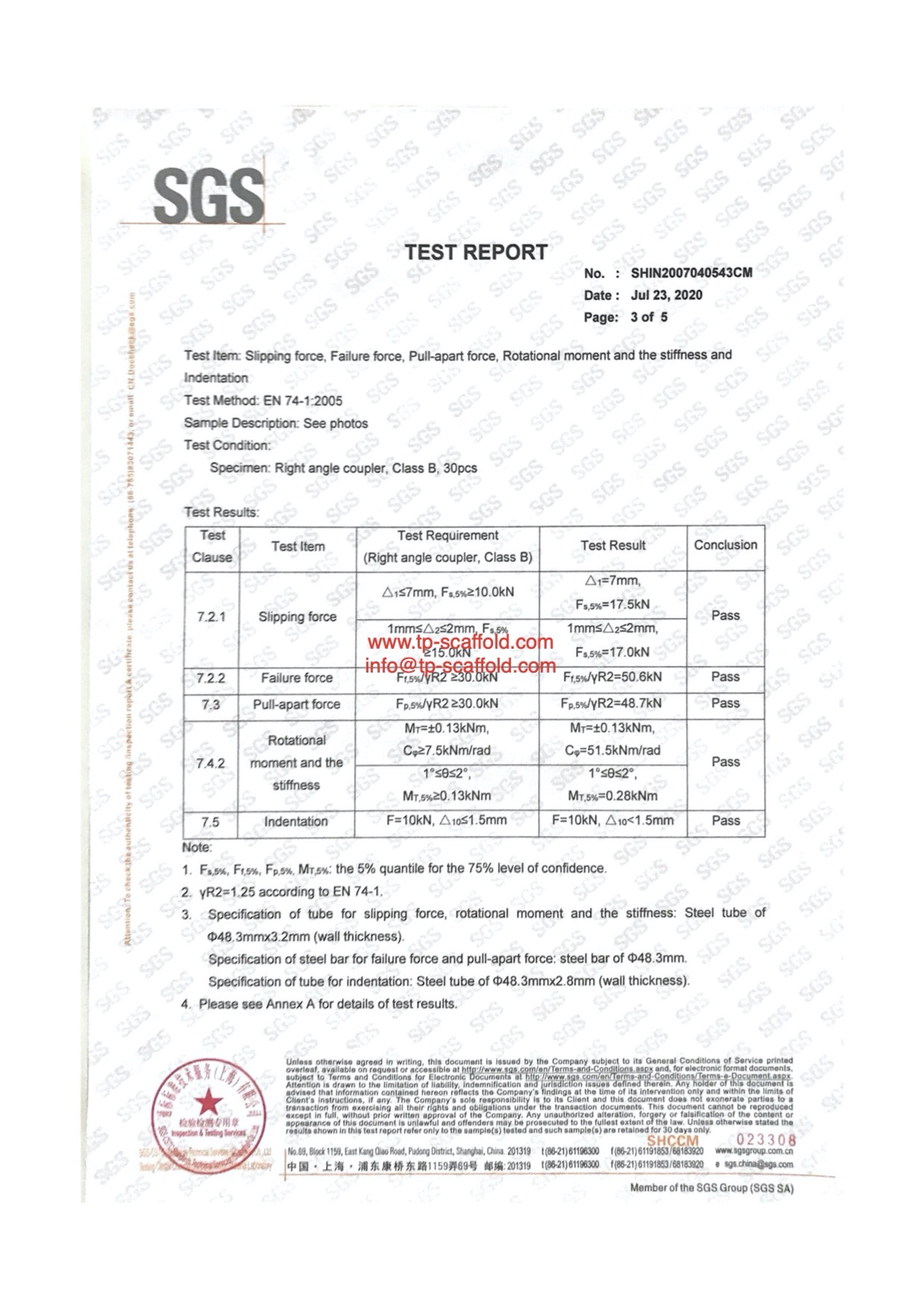

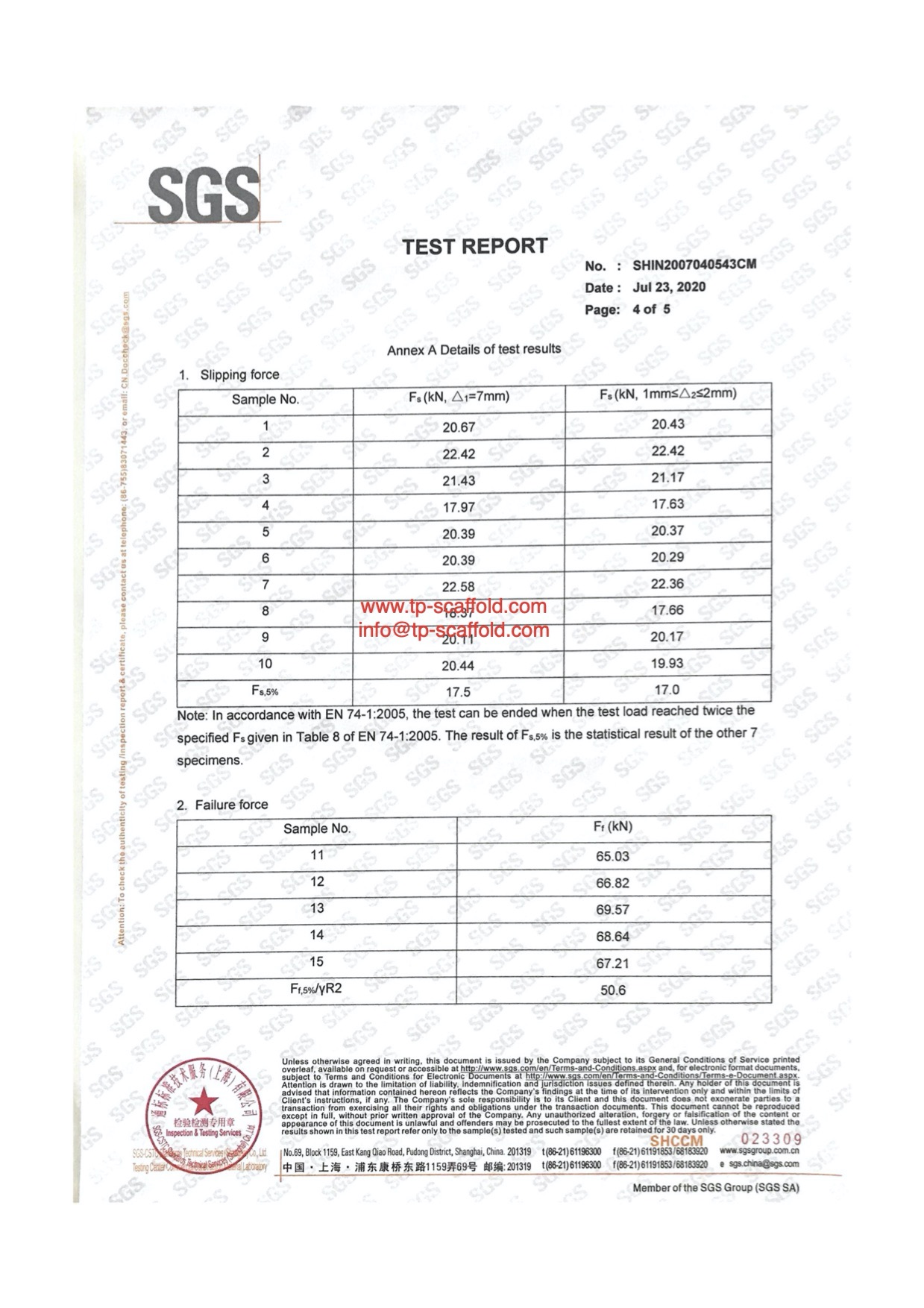

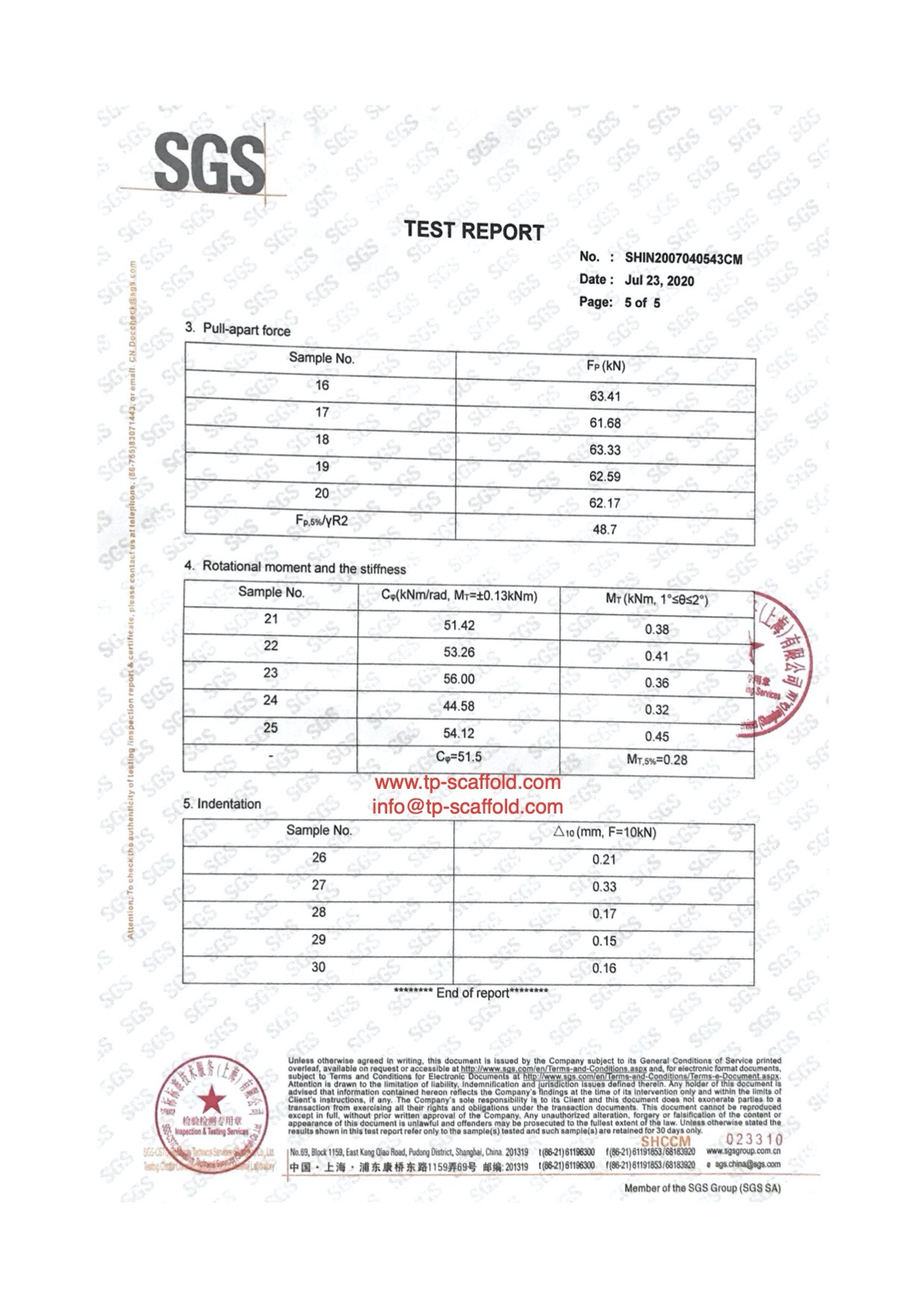

EN 74 Certificate for British style double coupler

FAQ

1.---What is your product range?

---Ringlock system, frame system, tubes and couplers, cuplock system, props, other scaffolding accessories and metal products.

2.---What is MOQ?

---Usually we don't have a strict MOQ, but it depends on the product you are looking for.

3.---Can I request samples? Is it free?

---Yes, we can offer free samples on most itmes if it is not too heavy or big

4.---Do you offer OEM service?

---Yes

5.---How you do the quality control?

---Our strict quality control system ensures all products well made step by step. All the raw materials are bought from professional steel manufacturers, with Mill Test Certificates offered. Our quality control persons inspect and monitor the whole process from raw material, cutting, pressing, welding, matching, surface finish, finishing process, packing, container loading and transportation.

6.---Do you have certificate?

---EN 74 certificate from SGS.

7.---What is production time?

---Usually it takes 25-30 days for the first container, production goes faster after the first container once all raw materials are ready. The more the faster. Partial shipment can be arranged if requested.

8.---What is your payment term?

---T/T is prefered. L/C at sight can be accepted in some area.

9.---What is your after-sale service?

---All the after-sale problems will be solved based on mutual friendly communication.

In case of quantity shortage, the detailed certificates should be sent to our side in seven days after the goods arrive at your warehouse. In case of quality discrepancy, such as problems caused by raw material, welding, or surface finish, the detailed certificates should be sent to our side. If it is confirmed caused by our side for the above two mentioned situations, the loss will be compensated as the new goods sent to your side in next order.