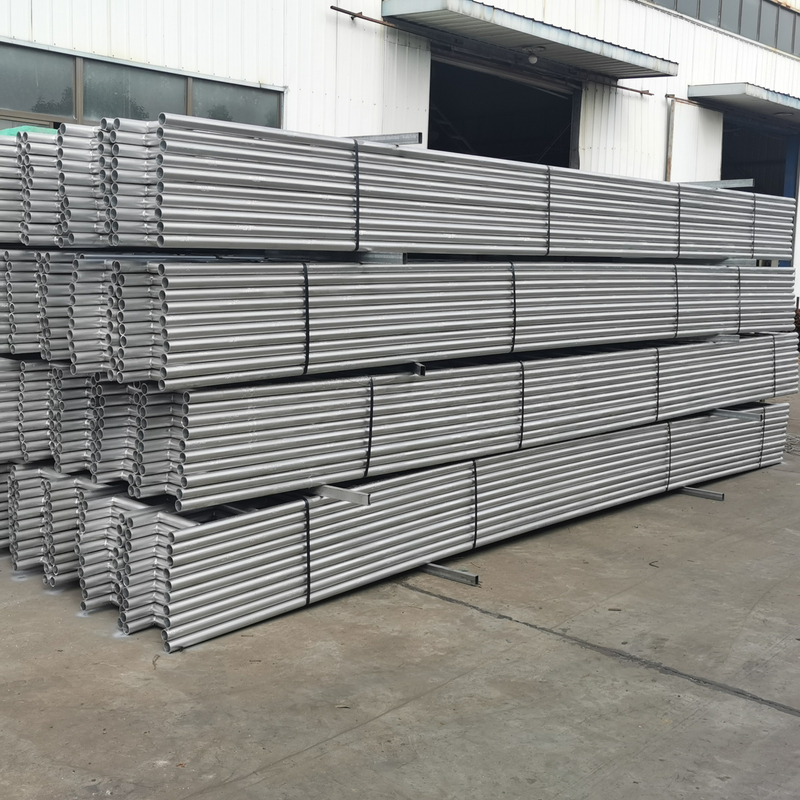

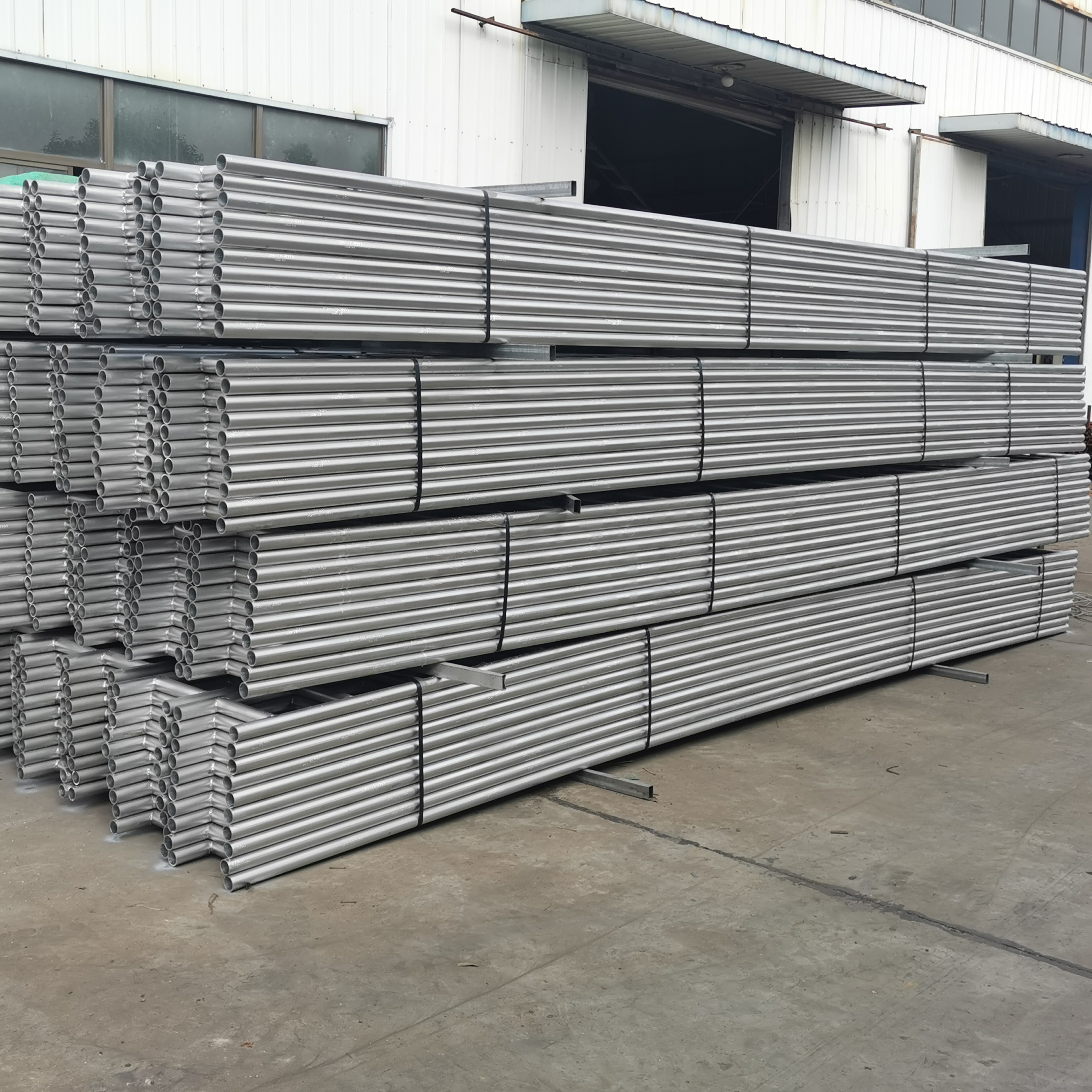

Galvanized Pipe Scaffolding Ladder Beam

Description:

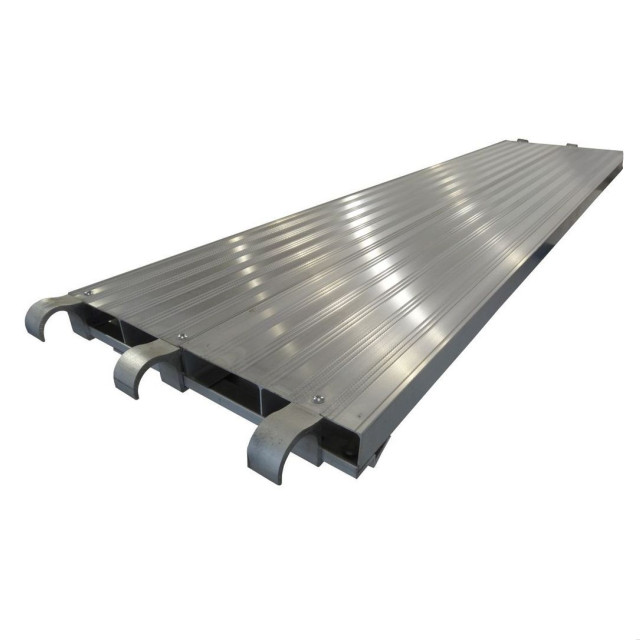

The Galvanized Pipe Scaffolding Ladder Beam is a robust and reliable horizontal scaffold component designed to provide essential structural support for scaffolding systems. Crafted from high-quality galvanized steel, this ladder beam is engineered to withstand heavy loads and harsh construction environments. Its durable construction ensures a safe and secure platform for workers and materials.

Application:

This Galvanized Pipe Scaffolding Ladder Beam finds its application in various construction and industrial projects. It serves as a vital horizontal connection between vertical scaffold standards, enabling the creation of a stable and secure working surface at elevated heights. The ladder beam is widely used in tasks such as building maintenance, construction, painting, and other tasks that require safe and accessible elevated access.

Advantages:

Exceptional Strength: Constructed from galvanized steel, the ladder beam offers remarkable strength and load-bearing capacity, ensuring the safety of workers and materials.

Corrosion Resistance: The galvanized coating provides excellent corrosion resistance, making the ladder beam suitable for outdoor and challenging environments.

Easy Assembly: The ladder beam's design allows for easy and efficient assembly, reducing labor time and increasing productivity on the job site.

Versatile Compatibility: It is compatible with various scaffolding systems and components, offering flexibility in design and application. Ladder beams are constructed using OD48.3mm steel pipes and can be connected to other ladder beams, steel pipes, and scaffolding systems such as Ringlock, Cuplock, Kwikstage, and others using couplers.

Enhanced Safety: The ladder beam's stability and secure attachment contribute to a safer work environment, minimizing the risk of accidents.

Longevity: Galvanized steel construction extends the ladder beam's lifespan, ensuring reliable performance over an extended period.

Regulatory Compliance: The ladder beam meets industry standards and regulations, further contributing to the safety and legality of its use.

Scaffolding ladder ladder beam specifications

1. Scaffolding ladder beam is very widely used for construction projects

2. Material: Q235 galvanized steel tubes

3. Out diameter: 48.3mm

4. Wall thickness: 3.2mm or 4mm

5. The width/ depth: 300mm, 400mm, or other width as requested

6. Different lengths are available: in the range of 610mm to 10m. Include popular length of 6m, 5m, 4m(13′), 3m, 2m, 6.4m(21′), 4.8m (16′). The longest scaffold ladder beam could be 8m and 10m.

Surface Finish Options for Ladder Beams

Two primary surface finish options are available, each offering distinct advantages in terms of protection and cost-effectiveness.

Option 1: Black Tubes with Post-Weld Hot Dip Galvanizing

Process: This method involves using black tubes for the initial construction of the ladder beams. After welding, the beams are then subjected to a hot dip galvanizing process.

Advantages:

Enhanced Protection: The post-weld hot dip galvanizing provides a robust and uniform zinc coating that offers superior corrosion resistance and durability.

Long-Lasting: This method ensures that the ladder beams are well-protected against rust and corrosion, extending their lifespan significantly.

Disadvantages: This process is more expensive due to the additional steps involved in galvanizing after welding.

Option 2: Using Pre-Galvanized Tubes for Welding

Process: This method utilizes pre-galvanized tubes for welding the ladder beams. The tubes already have a zinc coating, which is slightly compromised during the welding process.

Advantages:

Cost-Effective: Using pre-galvanized tubes is more cost-effective compared to the post-weld galvanizing method.

Efficiency: This process is more streamlined, reducing production time and costs.

Disadvantages: compromised Zinc Thickness: The welding process can reduce the thickness of the zinc coating, potentially affecting the long-term corrosion resistance of the ladder beams.

| Name | scaffolding ladder beam |

| Type | TPSLB001 |

| Material type | steel |

| Color | Can be required |

| Advantages | Top quality, Competitive price, Timely delivery, Good Service, Standard package, |

| Minimum order | 1 piece |

| Supply ability | 20 containers/ month |

| Port | Nanjing/Shanghai |

| Currency | USD,RMB |

| Payment | L/C, T/T, 30% in advance |

| Package | Steel Pallet |

| Delivery | according to quantities to be needed |

Production details: galvanized tubes are cut into right lengths and then to be welded, sprayed zinc paint.

Loading

Aluminum ladder beams are available here at Tuopeng Scaffold, too.

No matter you are distributors, contractors, or factories, you will always find what you need from us. We are committed to be honest and reliable scaffolding supplier and manufacturer, pursuing long-time cooperation relationship. Your money is always safe with us. Although our workday is from Monday to Friday, we are available to any of your requirement 7 days a week, 24 hours a day.

By choosing our Galvanized Pipe Scaffolding Ladder Beam, you are investing in a product that combines strength, reliability, and ease of use. Contact us today to place your order and experience the quality that sets us apart from the competition.

Hot Tags: Scaffolding Ladder Beam, Scaffolding components, Galvanized Scaffolding Ladder Beam, Scaffold Ladder Beam, scaffolding equipments for consctruction, Construction scaffolding ladder beams, Constrcution scaffolding materials, China, Custom, Private Label, buy, Quality, Advanced, durable, manufacturers, manufacturing company, suppliers, factory, free sample, made in China