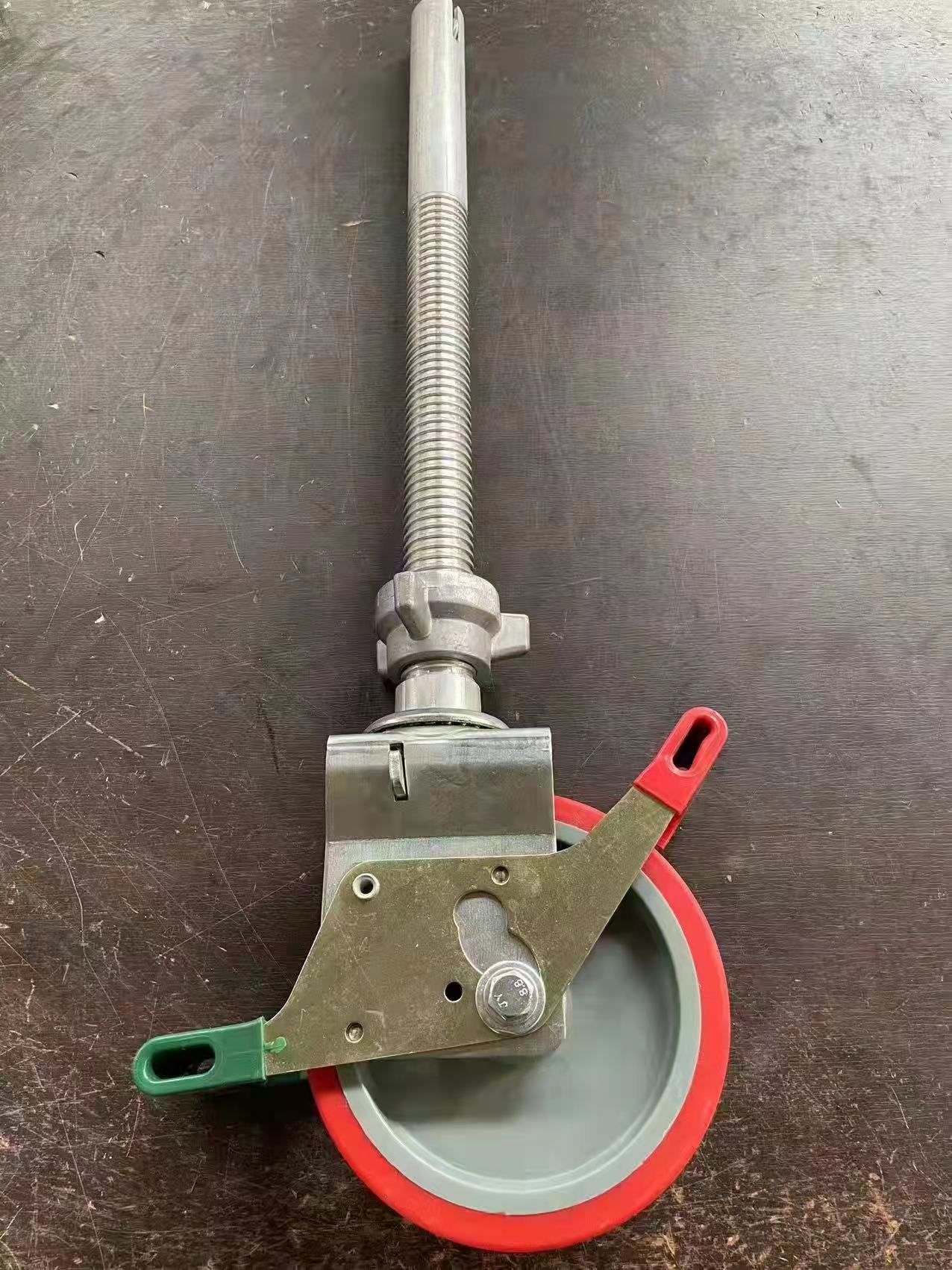

Adjustable Scaffolding Casters

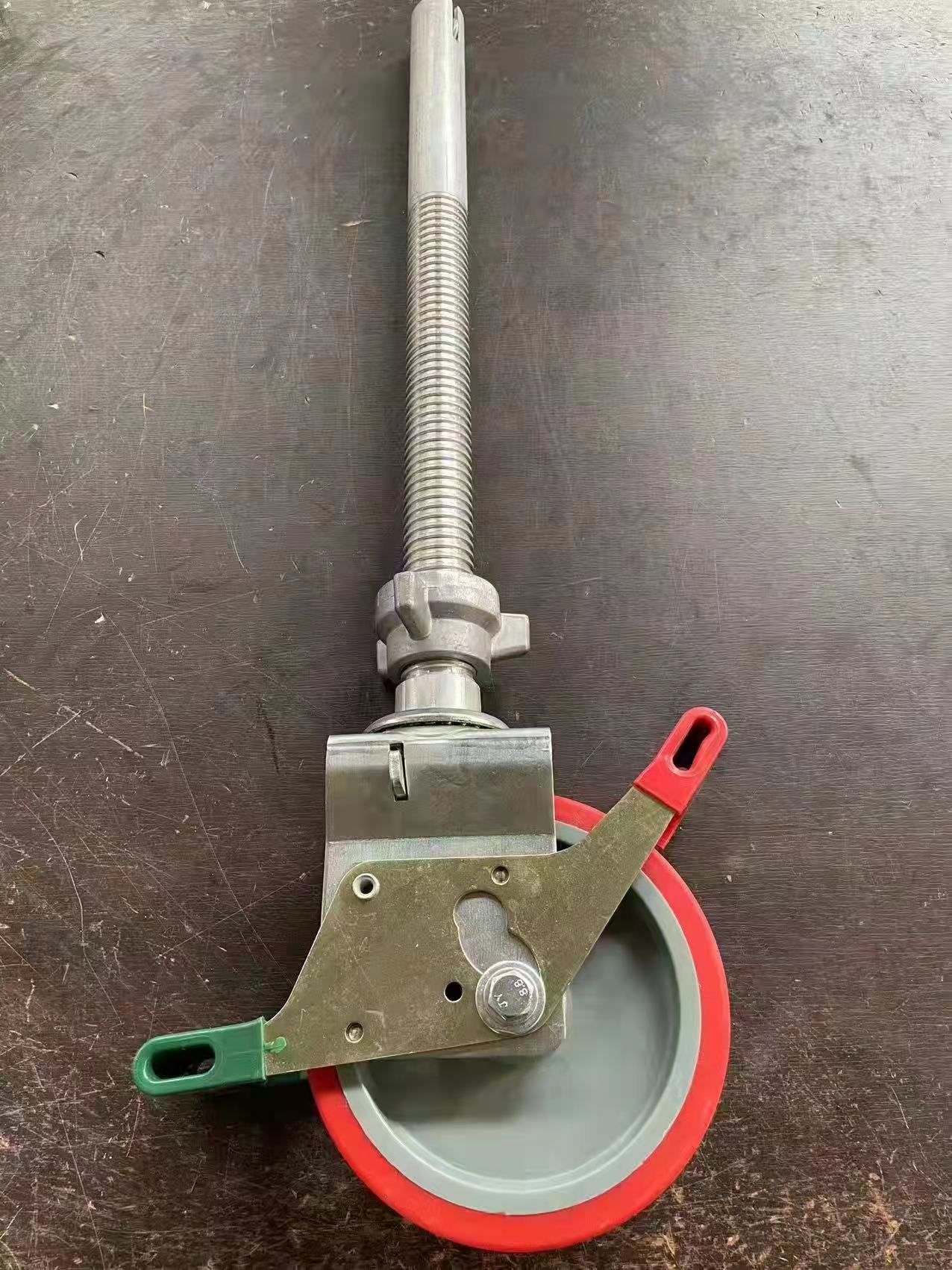

Adjustable scaffolding casters, also known as scaffolding caster jacks, scaffold tower adjustable wheels, or leveling jacks with casters, are essential components of mobile scaffold towers. These innovative casters combine the functionality of caster wheels with the adjustability of scaffold jacks, providing a stable and mobile platform for

construction work.

Key Features

Integrated Design: Adjustable scaffolding casters integrate flat plates and an adjustable scaffold jack base, allowing for precise height adjustments and stable support.

Leveling and Mobility: In building construction, these casters help level the height of mobile scaffolding towers, ensuring stability and safety. The scaffold caster wheels also enable easy movement of scaffold towers, making them motorized and highly efficient.

Components

Caster Wheels with Brakes: Provide mobility and stability, with brakes to ensure the scaffold remains stationary when needed.

Adjustable Jack: Allows for height adjustments to level the scaffold on uneven surfaces.

Jack Nut: Secures the adjustable jack in place.

Base Plate: Connects the wheel to the scaffold, distributing the load evenly.

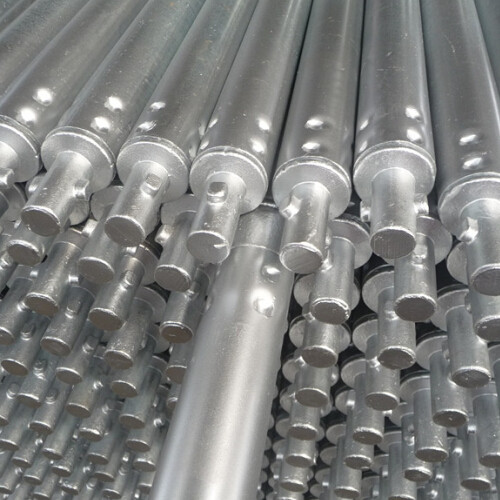

Connectors/Couplings Pins: Can replace the adjustable jacks for compatibility with system scaffolding vertical poles, though this eliminates the adjustability feature.

Material

Wheels: Made from durable materials such as rubber, PU, or PP.

Jacks and Nuts: Constructed from high-grade steel for strength and durability.

Sizes

Available in various sizes to accommodate different scaffolding systems and load requirements:

Wheel Sizes: 5”, 6”, 8”, 10”, and 12” adjustable scaffolding wheels.

Adjustable Length of the Jack: Ranges from 300mm to 1000mm.

Surface Finish

Electro galvanized for enhanced corrosion resistance and durability, ensuring long-term performance in harsh construction environments.

Load Capacity

The caster wheels have a load capacity ranging from 300 to 800 KG. Heavy-duty adjustable scaffold wheels can support weights from 9KN to 20KN, making them suitable for robust construction projects.

Types of Adjustable Scaffolding Casters

1. Adjustable Scaffolding Casters with Jacks:

Outer Diameter of Jacks: Must match the scaffolding pole sizes. For example, OD48.3mm scaffold standards require 38mm diameter scaffold stem adjustable scaffold wheels, while OD60mm heavy-duty scaffold poles require OD48mm diameter adjustable scaffolding wheel stems.

2. Adjustable Scaffolding Casters with Connectors:

Compatibility: Designed to be compatible with system scaffolding vertical poles, ensuring a secure and stable connection.

Adjustable scaffolding casters are a versatile and essential component in the construction industry, providing both stability and mobility for scaffolding structures. Their adjustable design, durable construction, and compatibility with various scaffolding systems make them an indispensable tool for a wide range of construction applications.

Daily Scaffold Caster Wheels Maintenance

Ensuring the longevity and safety of your scaffold caster wheels is crucial for efficient and secure construction operations. Our professional caster wheels are designed for durability, but regular maintenance is essential to keep them in optimal working condition. Here are some key maintenance tips to help you extend the life of your scaffold casters:

Install Scaffold Casters in the Correct Location

Ensure that the scaffold casters are installed in suitable locations to support the scaffolding structure properly. Incorrect installation can lead to instability and potential safety hazards.

Do not alter or disassemble the structure of the scaffold casters. Modifying the casters can compromise their structural integrity and safety.

Regularly Inspect All Parts

Conduct regular inspections of the scaffold casters to ensure all parts are securely fastened, especially the brake mechanism. A loose or malfunctioning brake can lead to accidental movement of the scaffolding.

Use Nuts or Washers During Installation

When installing the casters, make sure to use nuts or washers to secure them properly. This ensures a stable connection and prevents the casters from becoming loose over time.

Apply Lubricating Oil Regularly

Regularly lubricate the wheels and bearings to ensure they can operate smoothly for an extended period. Lubrication reduces friction and wear, prolonging the life of the casters.

Remember to check the scaffold caster wheels for signs of wear and tear regularly. Worn-out wheels can affect the mobility and stability of the scaffolding, potentially leading to accidents.

Why choose our scaffold caster wheels?

Our caster wheels are available in a wide variety of size, mounting, material and capacity to help you find the correct scaffold casters for your scaffolding tower with durability performance.

Common type caster wheels for option

Hot Tags: Adjustable Scaffolding Caster, Adjustable jack with caster wheel, 8" Caster Wheel for Scaffolding, 8 Inch scaffolding caster wheel, scaffolding caster wheel, Mobile scaffodling tower caster wheel, China, Custom, Private Label, buy, Quality, Advanced, durable, manufacturers, manufacturing company, suppliers, factory, free sample, made in China