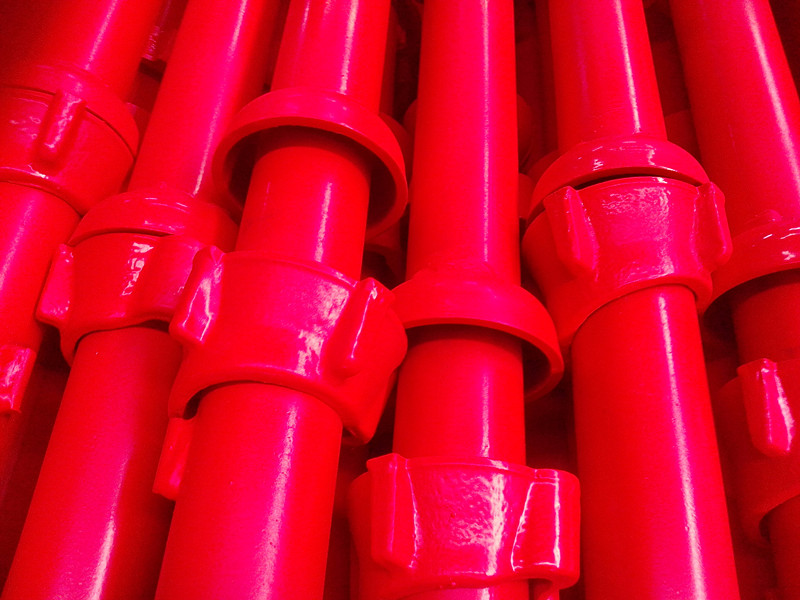

Cuplock scaffolding Standard/Vertical

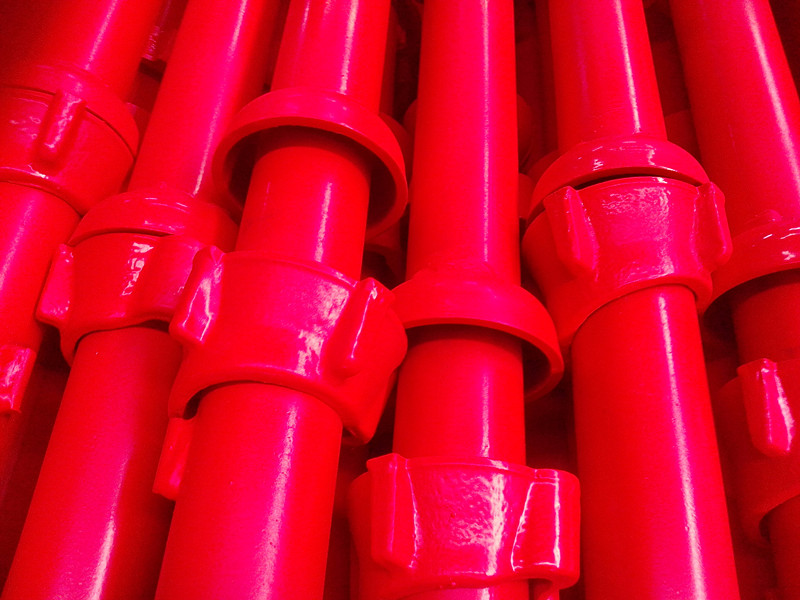

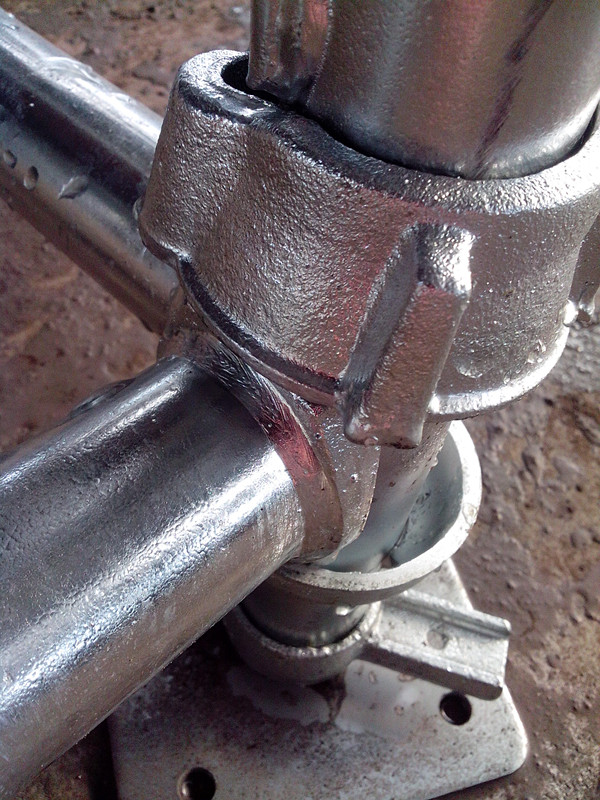

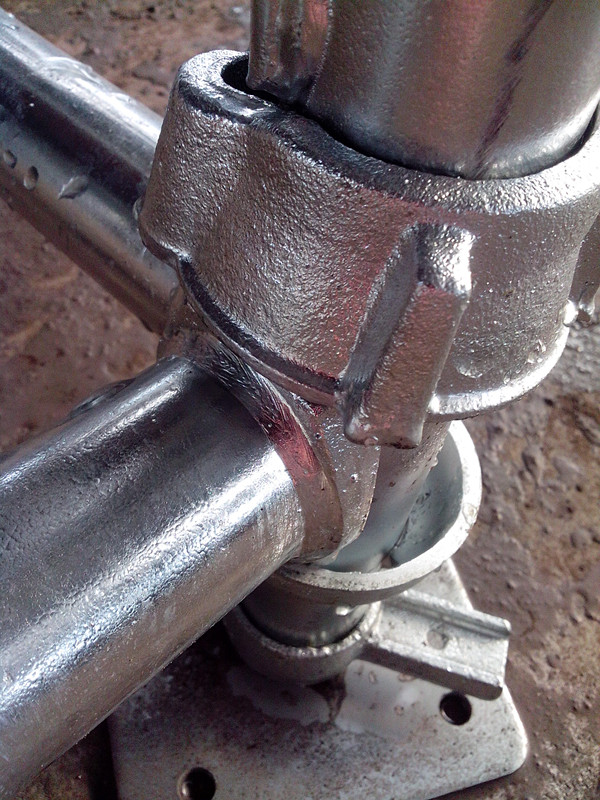

Cuplock scaffolding standard is made of 48.3mm tubes,with cup joints at every 500mm interval.The top cups are mobile,the bottom cups are welded.The work perfectly with ledger blade to lock the scaffolding safely.

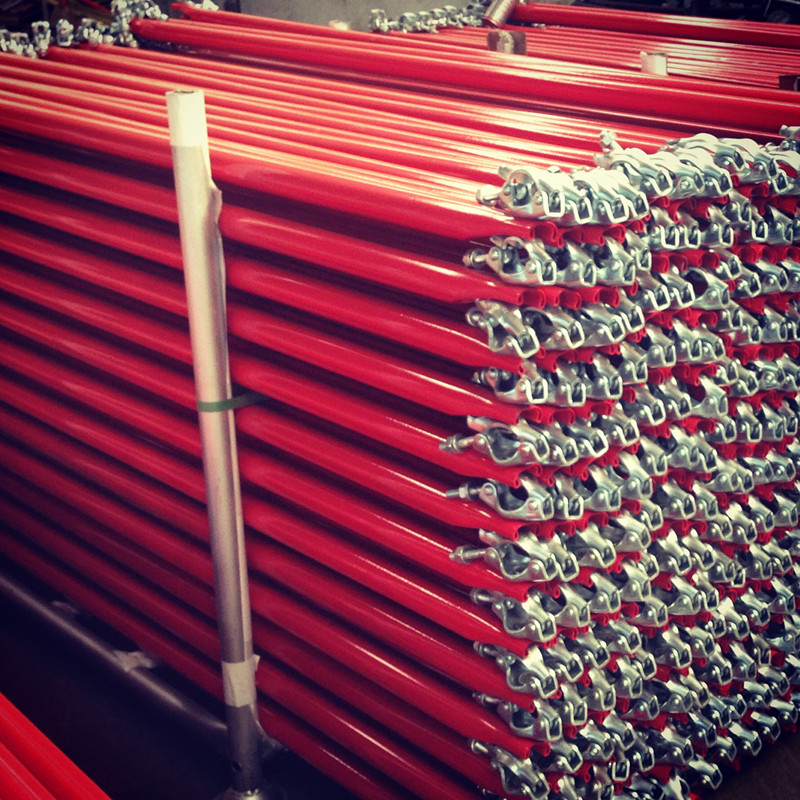

Surface finish:hot dip galvanised long lasting from rusted,powder coated or painted protecting the surface with less cost

Packing: steel pallet

Various sizes are available:

Description

Our Cuplock Scaffolding Standard with HDG Surface for Sale is a top-of-the-line construction solution designed to meet the highest industry standards. These standards are manufactured using precision engineering and feature a hot-dip galvanized (HDG) surface finish for maximum durability and corrosion resistance. Each standard is meticulously crafted to ensure safety, stability, and ease of use on construction sites of all scales.

Application

The versatility of our Cuplock Scaffolding Standards makes them an indispensable tool for a wide range of construction applications. They are suitable for:

Building Construction: Whether you're working on residential, commercial, or industrial projects, our standards provide the structural support needed for safe and efficient construction.

Bridge and Highway Construction: These standards are engineered to handle heavy loads, making them ideal for constructing bridges, overpasses, and highway infrastructure.

Industrial Maintenance: When it comes to maintenance work on industrial structures, our Cuplock Scaffolding Standards offer a stable platform for workers to access hard-to-reach areas.

Renovation and Restoration: Precise engineering ensures that these standards are adaptable for use in renovation and historical restoration projects, where stability and safety are paramount.

High-rise Construction: Thanks to their robust design, these standards are well-suited for tall structures, providing secure access for construction and maintenance tasks.

Advantages

Exceptional Durability: Our Cuplock Scaffolding Standards are manufactured with a hot-dip galvanized surface finish, providing excellent protection against corrosion and ensuring a long service life even in challenging environments.

Rapid Assembly: The cuplock system is known for its speed and simplicity when it comes to assembly. With minimal loose components, these standards can be quickly erected, saving valuable time on the job site.

High Load Capacity: Designed to handle heavy loads, these standards offer exceptional load-bearing capacity, providing a secure working platform for construction teams.

Safety: Safety is a top priority in construction, and our standards meet the strictest safety standards. Their robust design and secure locking mechanism provide peace of mind to workers and project managers.

Versatility: These standards are versatile and can be used in a variety of configurations, making them adaptable to different project requirements and site conditions.

Cost-effective: While they offer premium quality and durability, our Cuplock Scaffolding Standards are competitively priced, making them a cost-effective choice for construction projects of all sizes.

| Item Code | Length | Weight(kg) |

| TPCTCSS050 | 0.5 M | 3.53 |

| TPCTCSS100 | 1 M | 6.31 |

| TPCTCSS130 | 1.3M | 8.28 |

| TPCTCSS150 | 1.5 M | 9.05 |

| TPCTCSS180 | 1.8 M | 11.05 |

| TPCTCSS200 | 2 M | 11.82 |

| TPCTCSS230 | 2.3 M | 13.80 |

| TPCTCSS250 | 2.5 M | 14.57 |

| TPCTCSS280 | 2.8 M | 16.58 |

| TPCTCSS300 | 3 M | 17.34 |

Cuplock system scaffolding

Cuplock system scaffolding is designed and built to assist the most efficient construction projects.High quality,competitive price and fast delivery.

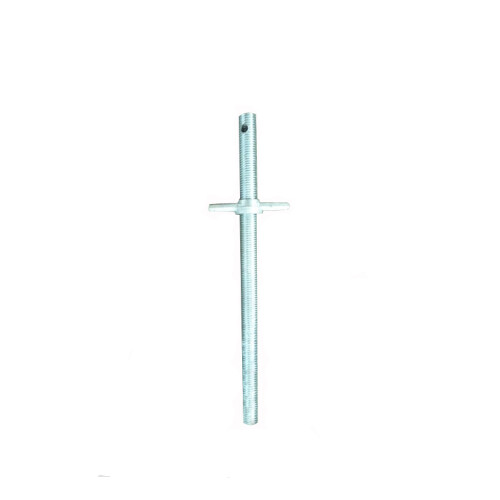

Components: verticals/standards,ledgers/horizontals,diagonal braces, brackets, steel planks,base jacks,ledger blades,top cup,bottom cup,etc.

Steel grade: Q235 and Q345

Surface finish: HDG,painted,etc.

Whether you are in the market for a complete scaffolding system, or just need accessories that are compatible with your current cuplock scaffolding system or your production, we are here to assist with your next building project or manufacturing need.

Hot Tags: Cuplock Scaffolding Standard, Cuplock Scaffolding, Cuplock Scaffolding Vertical, China, Custom, Private Label, buy, Quality, Advanced, durable, manufacturers, manufacturing company, suppliers, factory, free sample, made in China