Scaffold Adjustable Fork Head Jacks

Scaffold Adjustable Fork Head Jacks, also known as four-way jacks, are essential components in the construction industry. These versatile jacks are designed to provide stable support for formwork scaffolding and are compatible with various types of beams and scaffolding systems.

Components: Each scaffold fork head jack includes a screw jack stem, jack nuts (handle), base plate, and four pieces of steel angle forks. These components work together to ensure stability and adjustability.

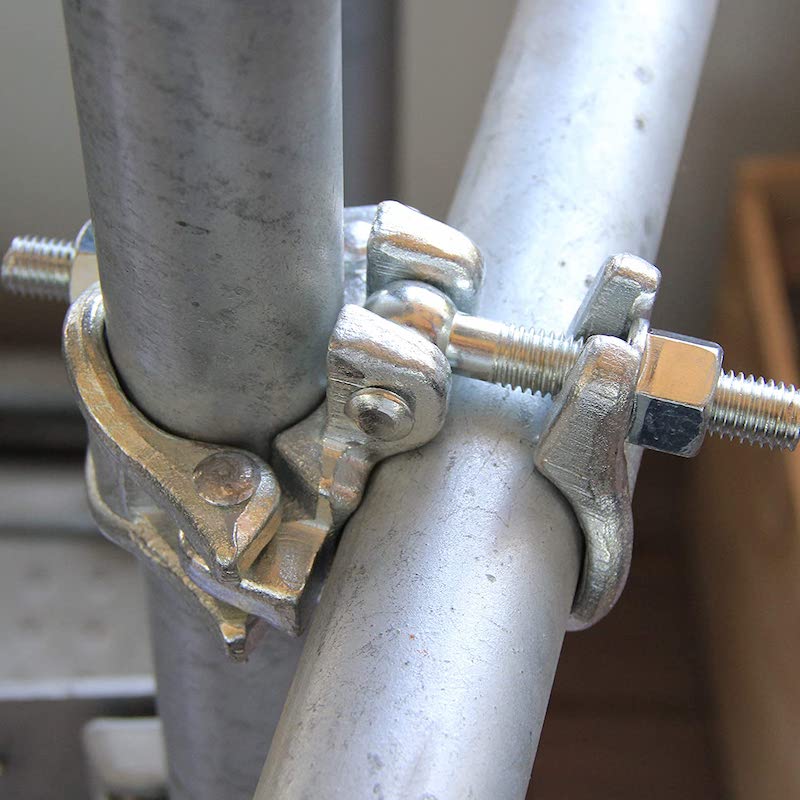

Usage: Primarily used to support formwork scaffolding, these jacks can be joined with all types of formwork beams, including timber, steel, and aluminum beams. They are also compatible with ringlock, cuplock, kwikstage, and shoring scaffolding systems.

We also supply the fork head only, which is more used together with the tripod. This option is ideal for projects requiring specific customization.

Specifications

System Scaffolding Compatibility: For scaffolding with 48.3mm vertical poles, the fork head jack diameter is 38mm. For shoring frame scaffolding or shore system ringlock with 60mm vertical poles, the diameter is 48mm.

Steel Grade: Available in S235 and S355 steel grades, ensuring durability and strength.

Overall Length: Ranges from 150mm to 900mm, providing versatility for different scaffolding heights.

Adjustable Range: Offers an adjustable range of 100mm to 750mm, allowing for precise height adjustments.

Packaging: Securely packaged on racks and pallets for easy transportation and storage.

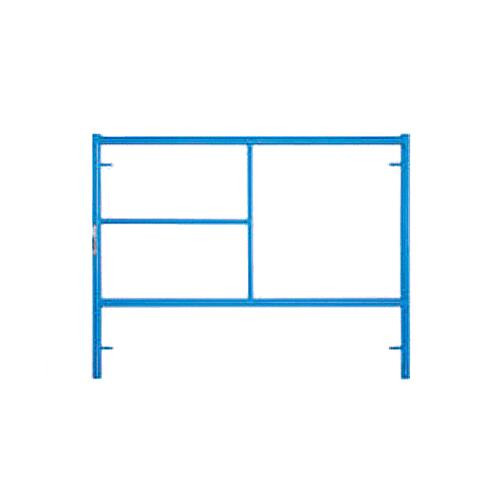

Types of Scaffold Fork Head Jacks

Hollow Type: More popular due to their lighter weight, cost-effectiveness, and sufficient loading capacity. They are ideal for most construction projects.

Solid Type: Heavier and more expensive, these jacks are less popular but are necessary for projects requiring a larger loading capacity.

Surface Finish Options

Painted: Provides a basic level of protection and is cost-effective.

Electro Galvanized: Offers moderate corrosion resistance and is suitable for indoor and outdoor use.

Hot Dip Galvanized (HDG): Provides the highest level of durability and corrosion resistance, making it ideal for long-term use in harsh environments.

Scaffold Adjustable Fork Head Jacks are indispensable tools in the scaffolding construction jobs, providing stable support for formwork scaffolding and compatibility with various scaffolding systems. With their adjustable height, durable construction, and versatility, these jacks ensure safety and efficiency on any construction site. If you want to know the price of the fork head jacks, or you have other specific need, please email us via: info@tp-scaffold.com.

Hot Tags: Scaffolding Adjustable Fork Head Jack, scaffolding fork head jack, scaffold fork head jack, Scaffolding Fork Head, China, Custom, Private Label, buy, Quality, Advanced, durable, manufacturers, manufacturing company, suppliers, factory, free sample, made in China